Waterproof panel PCs made of stainless steel are panel PCs with protection class (IP) that integrate both a touchscreen and powerful computing power. Various industrial computer manufacturers offer waterproof industrial panel PCs with different IP ratings, projected touch screens or resistive touch screens, function keys, etc. But more and more providers are also developing panel PCs made of stainless steel in the IP69K series. So does IPC2U GmbH.

What makes this type of monitors and system computing units superior compared to other materials?

Compared to standard panel PCs or HMIs (human-machine interfaces), waterproof panel PCs are protected against the ingress of solids and liquids due to their IP protection ratings. This is how waterproofness is explained using IP protection ratings.

However the typical IP69K stainless steel panel PCs can withstand vigorous washing and extreme environmental conditions such as freezing or hot temperatures, dust, seawater, heavy splashing water, shock and vibration from factory work, and more.

The IP69K rating means the device is protected against dust and strong 80°C jets of water. This type of protection is beneficial for industries where hygiene standards are important, such as: B. in food and beverage production, healthcare, chemical and pharmaceutical manufacturing, etc. Or for industrial applications where dusty and oily processes take place.

When washing equipment in industrial applications, healthcare and food processing, alkaline or acidic cleaning solutions are often used to remove stubborn stains and microorganisms on the equipment. Not to mention, advanced UV sterilization can damage the device. In oily processing plants such as meat processing, soap with high pressure hot water is often used to remove the fat.

This is where the stainless steel case offers advantages for computer technology as it has a unique ability to resist stains and corrosion. It is known that one of the special abilities of stainless steel is its ability to heal itself. The chromium content allows an invisible chromium oxide film to form on the surface of the steel. When the damaged stainless steel is exposed to oxygen - even in small amounts - it heals itself from mechanical and chemical damage.

With all the above features, powerful computing power and robust design are the best solutions for the successful deployment of intelligent industrial applications. However, some applications require more than just a waterproof panel PC.

Whether it's the actual processing of food or its packaging, automation is ubiquitous in today's modern food factories. Automating the factory floor helps keep costs down and food quality high. The stainless steel series is designed for the food processing, packaging and pharmaceutical industries where waterproof computer features that can withstand daily cleanings are required to ensure a clean food production facility.

HMI and industrial panel PCs for factory operations must function in changing dust, water splashes and moisture and meet the high hygiene requirements of certain industries.

Some industries have strict hygiene requirements. Machines, industrial displays and even factory halls have to be cleaned with hot water or chemicals.

Due to these high hygiene requirements, especially in the food industry, food processors and computer tools are subjected to extensive high-pressure and high-temperature cleaning.

The word: "corrosion" resistance immediately comes to mind.

Industrial panel PCs and HMI installed in a food processing or chemical factory are often wet, dusty and repeatedly cleaned with harsh chemicals that can easily cause corrosion.

That's why SUS 316 / AISI 316 stainless steel is the first choice when it comes to product design.

Panel PCs from the new IPC2U Stainless series combine an elegant design with a robust construction for industrial food, beverage and pharmaceutical applications.

Benefit from flexible mounting options, high performance and IP69K/IP65 standards for ultimate water and dust resistance.

The stainless steel alloy is corrosion resistant to meet specific industrial health and safety requirements.

The hygienic industrial solutions from IPC2U GmbH include the following model series:

- IP65 stainless steel SUS316/AISI316 B-Series with push buttons available in 15”, 19”, 21.5”

- IP69K stainless steel panel PC P series available in 15”, 19”, 21.5”, 23.8”

- IP69K stainless steel chassis PCAP panel PC available in 10.4”, 15”, 17”, 19”, 21.5”, 23.8”

- IP65 Stainless Steel SUS316 / AISI316 PCAP Chassis Panel PC available in 15”, 21.5”, 23.8”

- IP67 Resistive Chassis Panel PC available in 10.4”, 15”, 17”, 19”

The core function and advantages of these series are:

Water and dust protection IP69K/IP67/IP65.

The IP Code, International Protection Marking, IEC Standard 60529, sometimes interpreted as Ingress Protection Marking, classifies and rates the degree of protection of mechanical and electrical enclosures against ingress, dust, accidental contact and water. The Ingress Protection (IP) rating indicates that the device is waterproof and dustproof. For example, the IP65 level indicates that the device's housing does not allow dust to enter, is fully protected against contact (dustproof) and is protected from water jets.

- IP69K stainless steel WTP-9H66 Panel PC Series available in 15”, 19”, 21.5”, 23.8”

- IP69K Stainless Steel WTD Display Series available in 15”, 19”, 21.5”

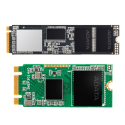

- IP69K stainless steel embedded PCs with Intel Core 12 Gen or Celeron J6412 available, WTC-9H0, WTC-8J0

- IP69K Stainless Steel GOT815A-TGL Panel-PC Series available in 15”, 18.5”, 21.5”