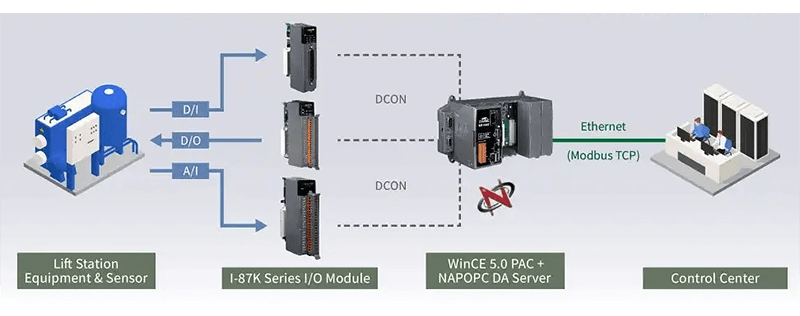

The implementation of ICP DAS WinCE PAC controllers and I-87K series I/O modules has created a modern monitoring system for five pumping stations located outside the treatment plant.

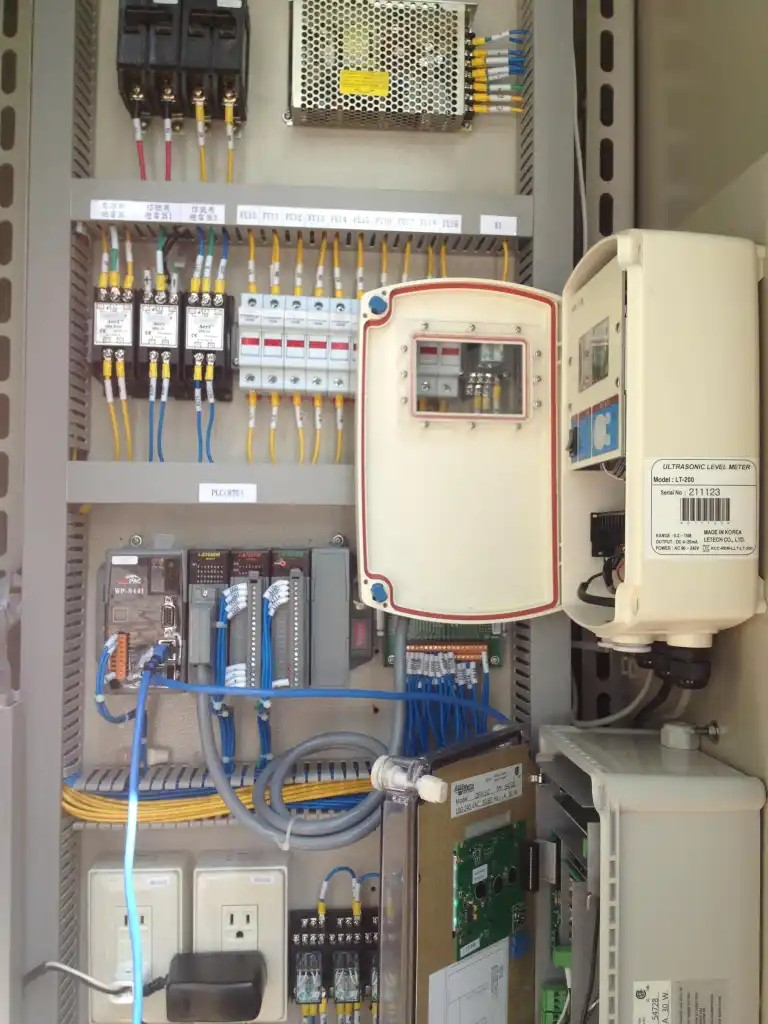

The central element of the system is the WP-8441* controller. It controls the operation of modules: I-87040W collects data on the operation of equipment (pumps, motors, valves), I-87017ZW monitors water level and pressure indicators, and I-87057W is responsible for managing field equipment. The NAPOPC DA Server software integrates all data and transmits it to the SCADA system, ensuring reliable and integrated operation of all components.

*The WP-8x41 series of controllers was discontinued in May 2022 and was replaced by the WP-8x21 series with Windows CE 7.0 operating system and a more powerful Cortex-A8 processor.

Introduction

Water is the most important resource in our lives. To ensure its purity and safety, municipal sewerage systems are created that transport domestic wastewater to treatment facilities. These systems support the sustainable use of water resources and prevent environmental pollution.

Pumping stations play a key role in such systems. Since water is moved in the sewer using gravity, lifting stations provide the necessary elevation difference, allowing you to overcome terrain obstacles: hills, tunnels, rivers.

For the largest in Taiwan, the Bali Wastewater Treatment Plant (New Taipei), ICP DAS developed an automated solution covering five lifting stations. Industrial-grade controllers collect data on the status of pumps, motors and valves, analyze them in real time and transmit them to the SCADA system of the central control room. This significantly improves the stability of the system and simplifies equipment management.

Intelligent system for pumping stations

Pumping stations come in two types: "wet" and "dry". In "wet" well systems, the pumps are immersed in wastewater, while in "dry" wells, they are located in separate isolated chambers. The equipment includes pumps, motors, check valves, filters, and sand removal systems.

The WP-8441 controller is responsible for station management thanks to its compact size, universal communication interfaces and four slots for connecting expansion modules. Compatible modules of the I-87K series supporting the DCON protocol provide:

-

Equipment monitoring: the I-87040W module collects data on the status of pumps, motors and valves. The information is transmitted to WP-8441 for processing and analysis.

-

Equipment management: the I-87057W module receives commands from the controller and controls the switching on/off of pumps and motors.

-

Water level and pressure control: the I-87017ZW module records data from water level and pressure sensors, ensuring stable operation of pumps and preventing overflow.

All data is transmitted to the central SCADA system via the Modbus TCP protocol, which allows automatic generation of alerts when the set limits are exceeded and sending notifications to responsible employees.

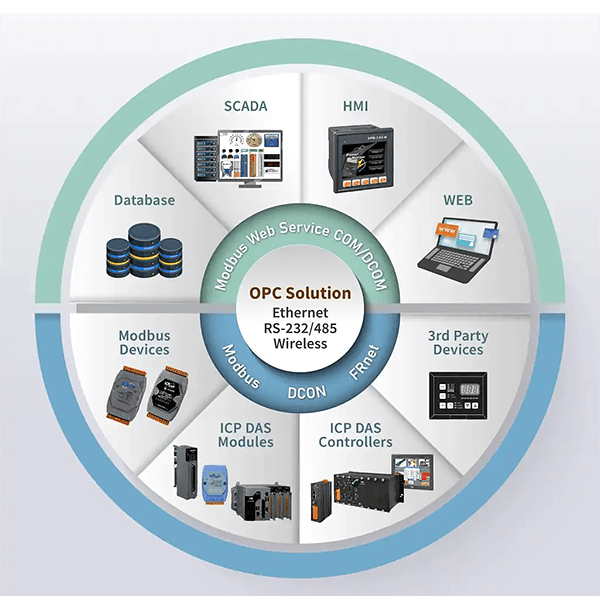

NAPOPC DA server

NAPOPC DA Server software centralizes equipment data and facilitates information exchange between pumping stations and SCADA systems. Thanks to its multi-threaded architecture, the server ensures high data processing speed, and automatic module detection and data structure creation simplifies system setup.

Equipment update: WP-8428-CE7 Win-GRAF PAC

After discontinuation of the WP-8441 WP-8421-CE7 or WP-8428-CE7 are recommended as an alternative, under the control of the WinGRAF development system. The new controller is equipped with a Cortex-A8 processor (1 GHz), supports modern communication protocols (Modbus TCP, DCON, HART) and works with I/O modules of the I-8K and I-87K series. Using the Win-GRAF (IEC 61131-3) development environment makes it easier to write control and monitoring applications.

The controller also features a backup power supply, a built-in dual watchdog timer and an On-Line Change function, ensuring reliable operation even in emergency situations.

Benefits of the solution

-

Effective monitoring: I-87040W and I-87057W isolated modules come with with LED indicators and interference protection, which simplifies operation in industrial conditions.

-

Optimization of service: based on the pump operating time data, maintenance and component replacement can be planned in a timely manner.

-

Water level and pressure control: prevention of blockages and overflows through continuous monitoring.

-

High reliability: backup power supply and failure protection ensure stable system operation.

Conclusion

The ICP DAS solution for monitoring pumping stations combines the reliability of PAC controllers, the flexibility of I/O modules and the powerful capabilities of SCADA systems. This approach not only minimizes the risks of downtime and accidents, but also significantly simplifies the management of the system, ensuring its stable operation in urban infrastructure conditions.