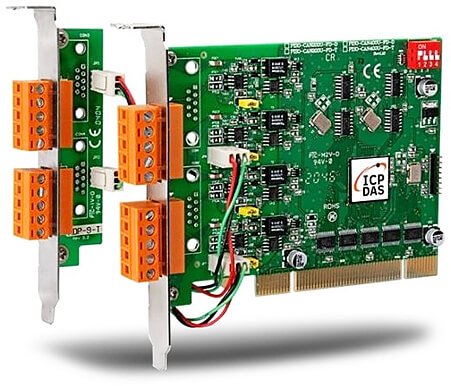

The new Universal PCI Extension Cards PISO-CAN200U-FD-D/T and PISO-CAN400U-FD-D/T use a robust design and support the CAN 2.0 A/B FD (CAN with flexible Data Rate) standard created in 2012 to enable optimized control of sensors and actuators with minimum latency even under difficult conditions. Depending on the scope of the connected peripherals, PISO-CAN200U-FD-D/T models for two and the PISO-CAN400U-FD-D/T variants for four separate CAN buses are available.

The importance of CAN Bus has shifted from automotive engineering, for example in cars, ships, and the aerospace industry, to industrial manufacturing and the monitoring of machines, plants, and power plants. The major advantages of the bus system, which was jointly developed by Intel and Bosch in the mid-1980s, include fast response times, high reliability, and clear prioritization and categorization of events. With the PISO-CAN200U-FD-D/T and the PISO-CAN400U-FD-D/T, corresponding structures can be set up with high efficiency and used both decentrally as a non-hierarchical network and for communication between external hardware and circuits and a control server.

In order to realize maximum compatibility in different environments including industrial processes based on older hardware, the PISO-CAN200U-FD-D/T and PISO-CAN400U-FD-D/T expansion cards use Universal PCI as an interface to the IT system. Due to this, they can be easily integrated into new and existing environments and offer, for example, various possibilities for server consolidation through virtual machines with exclusive or collective access to external devices. The two variants differ only in the number of independent CAN bus systems, which is two for the PISO-CAN200U-FD-D/T and four for the PISO-CAN400U-FD-D/T, physically separated ports located on panels for expansion cards. The letter D or T after the connector refers to the type of interface: In the case of D, it consists of male DB-9 ports, as used for Serial COM, for example, and in the case of T, it consists of terminals with screw connections for the individual cables.

For use in harsh environments, the PISO-CAN200U-FD-D/T and PISO-CAN400U-FD-D/T plug-in cards are designed to operate at temperatures between 0° and 60° Celsius and do not require active cooling or open ventilation. This robust design allows installation in classic industrial computers without IP protection level as well as in embedded servers sealed to IP65 or higher. To safely isolate the two circuits from each other, the PISO-CAN200U-FD-D/T and PISO-CAN400U-FD-D/T protect their connections with photoelectric protection circuits and feature isolation for voltage spikes, inductions and short circuits up to 3000 VDC. Operating system compatibility includes various versions of Microsoft Windows 7 to 10 including the required drivers in 32 bit/64 bit as well as Linux distributions and Real Time Operation Systems (RTOS) based on them.

On the software level, there are extensively documented demos and libraries for the quick and uncomplicated programming of own applications in different programming languages including C#.Net, VC++ Net and VB.Net, on the basis of which own routines can be created, written and tested with little effort. Communication via the PISO-CAN200U-FD-D/T or PISO-CAN400U-FD-D/T can be done either according to the traditional linear method of the technology or alternatively via more complex structures with a central master and numerous slaves within a star topology.

One focus of the two models PISO-CAN200U-FD-D/T and PISO-CAN400U-FD-D/T is the modernization of existing industrial IT systems in the context of process optimization and upgrades for the hardware. Another, on the other hand, on the creation of new systems and informative networks for Industry 4.0 tasks and an exact scaling and optimization of digital communication with minimum latency between CAN bus, control and measuring devices. Regardless of their purpose, the PISO-CAN200U-FD-D/T and PISO-CAN400U-FD-D/T expansion cards provide a convenient method of networking modern IT infrastructure with secure, reliable and efficient complex systems for automating processes.