What Are the Key Advantages of Integrated Flash Storage?

These compact storage solutions provide high-speed data transmission within an incredibly small footprint, making them ideal for space-constrained industrial systems. They offer superior resistance to physical shock and vibration due to their soldered design, ensuring long-term data integrity in harsh operating environments.

Information technology is expanding deeper into our everyday lives, increasing the demand on IT products. To meet this challenge, IT solution providers are advancing the technology, constantly reducing workflows and improving solution performance.

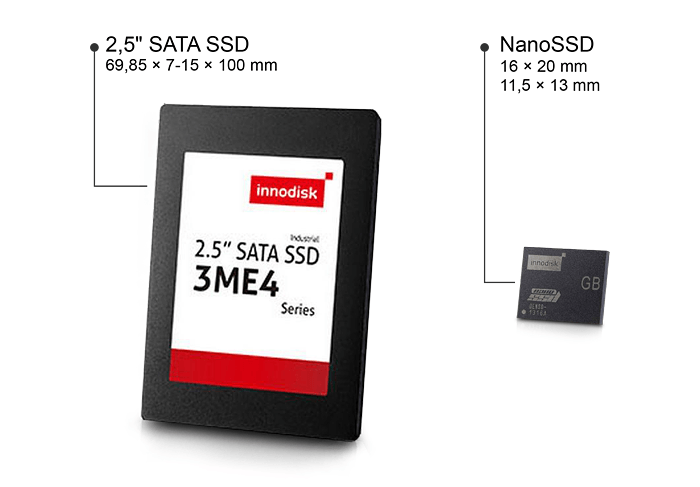

The massive introduction of IT systems and mobile computing has affected the requirements for component size and weight. Data storage systems are no exception. As of now, the most popular form factor for storage systems is the 2.5” SATA.

The 2.5” form factor was first proposed by PrairieTek in 1988 and has gained a long-standing popularity in PC design. Drives of this form factor are 100 mm long, 69.85 mm wide and 5 to 19 mm high.

As the technology has advanced, 2.5” SATA have met some competition fr om the mSATA and M.2 standards. These SSDs are capable of storing the same terabytes of data in much smaller dimensions.

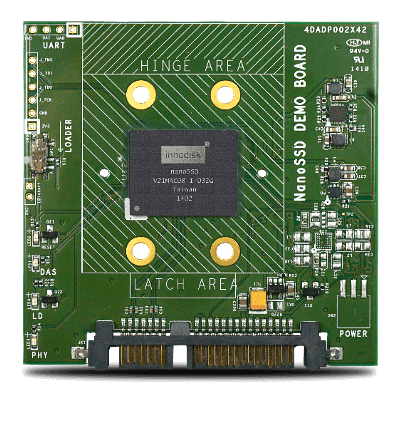

Despite significant reduction in storage systems dimensions and their improved connectivity, compact embedded systems required an even more radical solutions. Avoiding the spontaneous disconnection of the carrier from the data bus, storing tens of gigabytes of information, the speed and reliability of a classic drive, but at the same time a much smaller size and weight – these were the requirements. And the solution is a new line of industrial-grade embedded SSDs – Innodisk’s nanoSSD.

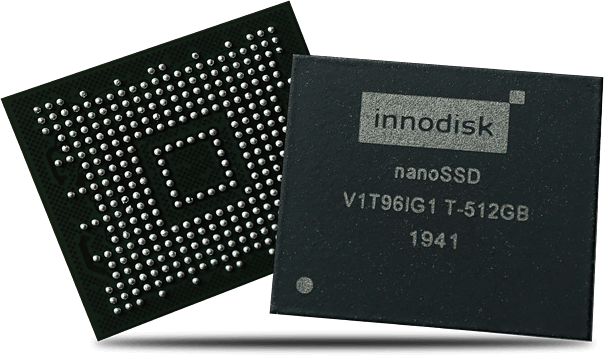

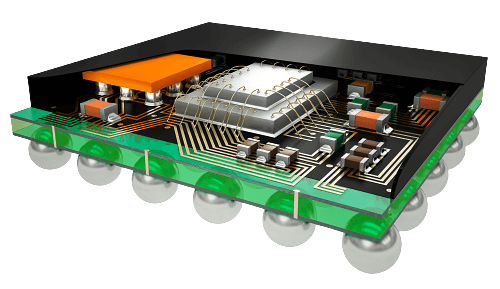

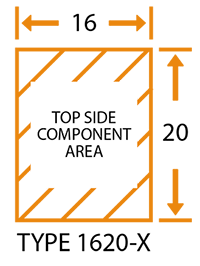

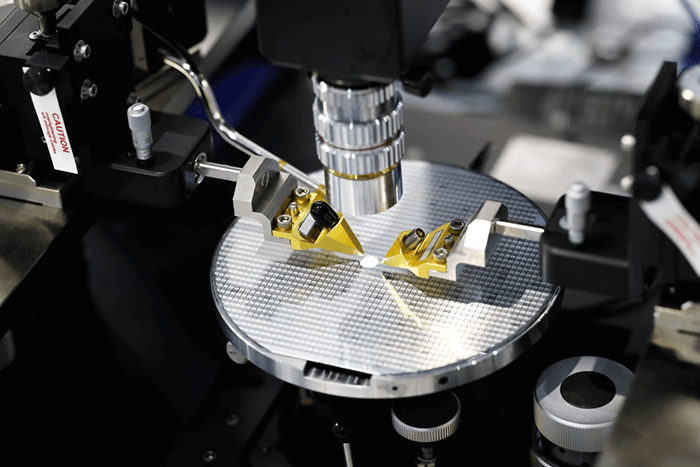

The nanoSSD drive, also known as BGA (ball grid array) SSD is a surface-mounted integrated circuit with a size of 16 x 20 or 11.5 x 13 mm and a weight of just 0.5 grams. The microcircuit consists of flash memory, the controller, and secondary logic cells.

BGA pins are small balls of solder fixed to the contact pads on the back of the microcircuit.

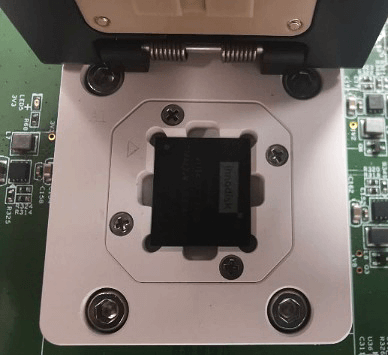

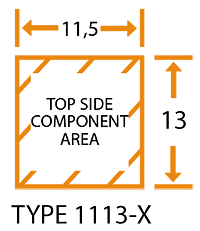

The microcircuit is located on the circuit board, according to the first contact marking. Then the microcircuit is heated using a soldering station or an infrared source so that the BGA balls begin to melt.

Surface tension forces the molten solder to fix the chip exactly wh ere it should be on the board.

Innodisk nanoSSD is a highly integrated flash drive designed with SiP (System-in-Package) technology

What are integrated flash storage modules and how do they function?

This product type consists of a single-chip micro-sized drive that combines a controller and flash memory into a specialized ball grid array package. By being mounted directly onto a motherboard, they eliminate the need for traditional cables and connectors, which reduces the overall size of industrial computing hardware.

System-in-Package technology enables the packaging of electronic components in a single housing as a complete, fully functional system. An electronic device of this type usually contains two or more different crystals, combined with passive elements, filters, antennas and mechanical parts. These components together form a highly integrated product.

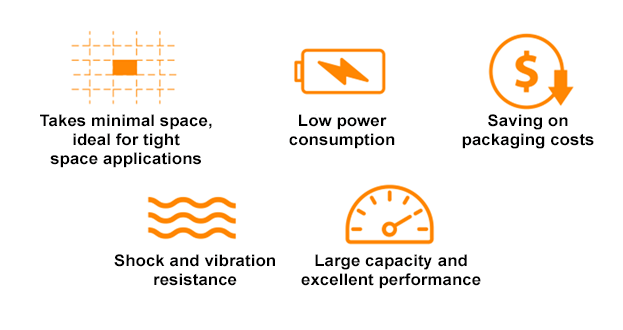

Innodisk nanoSSD is a very small device with high component density. Less storage space means more space for other system components.

Compared to a classic 2.5” SATA, nanoSSD size has decreased by 95%, its weight having decreased hundredfold. This allows the drive to fit into virtually any compact computing device.

The nanoSSD form factor has the following advantages:

Innodisk nanoSSD series

There are three distinctive series among Innodisk nanoSSD drives. Each of them has its own characteristics:

| Model name | SATA 3ME3/3IE3 | SATA 3TE7 | PCIe 3TE7 |

|---|---|---|---|

| Interface | SATA III | PCI-Express Gen3x2 | |

| Form factor | 1620 (16х20 mm) | 1113 (11.5х13 mm) | |

| Flash type | MLC/iSLC | 3D TLC | 3D TLC |

| Capacity |

MLC: 16GB-128GB iSLC: 8GB-64GB |

32GB-256GB | 32GB-512GB |

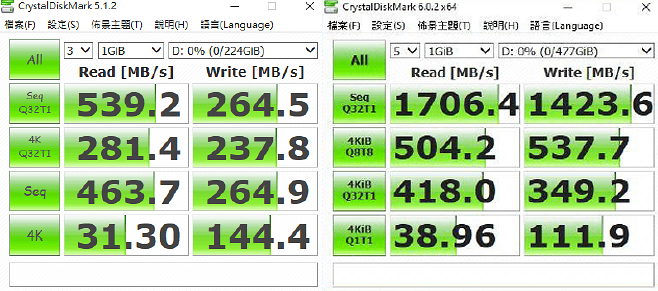

| Sequential R/W (MB/sec, max.) |

MLC: 410/140 iSLC: 440/260 |

540/260 | 1700/1400 |

| Operation Temperature |

0 +70 oC, -40 +85 oC |

0 +70 oC |

0 +70 oC, -40 +85 oC |

| Status | Mass production | Mass production |

3GB-256GB available in Q3 2021 512GB available in Q3 2021 |

SATA drives have a 16 x 20 mm form factor. Drives with different types of memory cells are available: 3D TLC, MLC, and iSLC, allowing you to choose the optimal solution by cost and requirements.

For different types of cells, the capacity also differs.

iSLC have the lowest capacity (64GB max.) but is the most durable. These drives deliver up to 20,000 complete rewriting cycles.

3D TLC drives have the largest capacity (up to 256GB), and the number of rewriting cycles reaches 3000.

MLC cells are “the golden mean”, offering a capacities up to 128GB and rewrite cycles up to 3000.

Who needs this products, such as micro-sized storage drives?

System designers and hardware engineers developing compact IoT devices or edge computing platforms require these components to maximize internal space. They are also essential for professionals in the automation and transportation sectors who need reliable storage that can withstand extreme temperature fluctuations and constant mechanical stress.

The operational temperature range also varies. The standard range is fr om 0° to 70°C, while the extended range is from -40° to +85°, allowing for a wider scope of application.

In addition, Innodisk has introduced the new super-compact 3TE7 series of nano-drives measuring only 11.5 x 13 mm with a PCI-Express interface. This series uses only 3D TLC memory cells.

3TE7 drives are available in both standard and extended temperature ranges.

The storage capacity is up to 512GB, with a read speed of 1700 and a write speed of 1400 MB/s.

3TE7 series specification:

- Extended operational temperature range -40 to +85 °C available

- NVMe 1.3 compliant

- Supports high-capacity 3D TLC cells

- AES-256 and TCG Opal 2.0 compatible

- Has LDPC ECC error correction mechanism and ETEP end-to-end data protection system

- Uses host memory buffer (HMB) for maximum DRAM-free performance

nanoSSD drive features

Compact dimensions

nanoSSD drive has a volume of 210 cubic mm; only 1% of the classic 2.5 SATA drive’s 63000 cubic mm.

The creation of a new SSD form factor consists of the design and layout of memory chips, controller, and logic elements on the board. This requires several stages of development, assembly, and production of various parts.

In the case of the nanoSSD drive, we have cut the cost of development and production in half. The nanoSSD is a complete functional diagram wh ere the controller, memory cells and logic elements are combined into one, compact BGA package.

Comparatively, when looking at the classic SSD setup, you must factor in the cost of development, assembly, and manufacturing. The nanoSSD avoids this by offering a fully function SSD in a single package.

| Model name | Standard solution (Controller + NAND flash), costs | nanoSSD (BGA SSD for SiP), costs | ||

|---|---|---|---|---|

| List of materials, components, blocks, individual parts of the final product | Coltroller | Controller matrix | ✔ | ✔ |

| Assembly cost | ✔ | — | ||

| Manufacturing cost | ✔ | — | ||

| Design cost | ✔ | — | ||

| NAND Flash cells | Flash matrix | ✔ | ✔ | |

| Assembly cost | ✔ | — | ||

| Manufacturing cost | ✔ | — | ||

| Design cost | ✔ | — | ||

| BGA SSD | Assembly cost | — | ✔ | |

| Manufacturing cost | — | ✔ | ||

| Design cost | — | ✔ | ||

Excellent protection against vibrations and shock

All nanoSSD components are tested under harsh vibration and shock conditions to ensure data integrity, even in the most demanding environments.

High capacity

Thanks to the multi-layered memory structure in the SiP block, the 1620 form factor can store up to 1 TB of data, and the 1113 form factor up to 512 GB.

Excellent performance

The nanoSSD shows high performance in sequential read/write, and significantly outperform universal USB 2.0 drives and eMMC memory.

Sequential read/write speed comparison:

| Model name | Sequential read (MB/s) | Sequential write (MB/s) |

|---|---|---|

| nanoSSD PCIe 3TE7 | 1700 | 1400 |

| nanoSSD SATA 3TE7 | 540 | 260 |

| UFS 2.0 | 480 | 170 |

| eMMC 5.0 | 260 | 140 |

Best power consumption

The nanoSSD is up to 24% more energy efficient in sequential write and up to 15% in sequential read compared to M.2 2280 SSD.

| Model name | M.2 2280 3TE7 | nanoSSD 3TE7 | Energy saving |

|---|---|---|---|

| Sequential read, current (mA) | 385 | 328 | 15% |

| Sequential write, current (mA) | 456 | 347 | 24% |

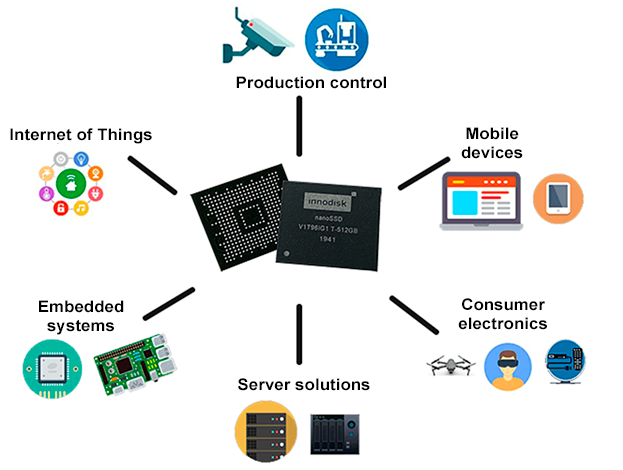

Versatility for different solutions

Due to its compact size, low power consumption, high speed performance, and industrial reliability, the nanoSSD can be used in a wide variety of applications:

- Both indoors and outdoors

- Transport and stationary solutions

- Video surveillance systems, for example, inside the housing of a secure camera

- Production control and management systems

- Mobile robots and unmanned aerial vehicles

- Embedded systems

- Mobile phones and tablet computers

- Internet of Things solutions

- As a boot sector for server systems

- And also in any maintenance-free device requiring a reliable, fast and compact storage solution

Innodisk has managed to combine the best features of the usual SSD and BGA chips. High speed, reliability, and good capacity have expanded the scope of SSD applications, and the highly integrated BGA form factors 1113-X and 1620-X have significantly saved PCB space and reduced the cost of new storage solutions.

It should be noted that, first of all, nanoSSD is a product aimed at system integrators and computer manufacturers, whose production lines allow designing solutions and soldering BGA microcircuits onto printed circuit boards.

Qualified specialists of both IPC2U and Innodisk companies are ready to provide full technical support throughout the entire development and production cycle of your final product.

Find a SSD solution just for you in our catalog:

How helps this products to facilitate industrial automation?

These integrated units enable the creation of smaller, more efficient control systems that can be deployed deep within production environments. By providing a stable and durable platform for local data processing, they help ensure that smart factory operations remain continuous and unaffected by the physical demands of the industrial site.