Introduction to Remote I/O Systems

Remote I/O modules and units are critical components in modern industrial automation systems, enabling the extension of control capabilities to distant locations without the need for extensive wiring. These devices serve as the interface between central control systems and field devices, collecting data from sensors and transmitting commands to actuators across large facilities or distributed processes.

What are remote I/O units and how do they function?

This product type serves as a critical interface between central control systems and distant field devices, utilizing various communication protocols to bridge the gap. They function by collecting real-time data from remote sensors and transmitting specific commands to actuators, ensuring seamless data exchange across large industrial facilities or distributed processes.

The primary advantages of remote I/O solutions include:

What Are the Key Advantages of Remote I/O Modules?

These essential components significantly reduce wiring costs and complexity by extending control capabilities to distant locations without the need for extensive cable runs. They provide a highly flexible system architecture that improves scalability while offering enhanced diagnostic capabilities and greater reliability through distributed control.

- Reduced wiring costs and complexity

- Flexible system architecture

- Improved scalability

- Enhanced diagnostic capabilities

- Greater reliability through distributed control

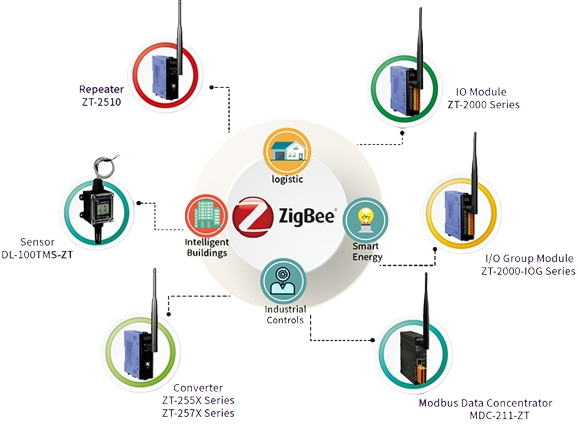

ZigBee technology offers robust wireless communication for industrial I/O applications, particularly suited for environments where wiring is impractical or too expensive. The self-forming, self-healing mesh network architecture ensures reliable data transmission even in challenging industrial environments.

Featured ZigBee Products:

- ICP DAS - ZT-2551 ZigBee-to-RS-232/422/485 converter with transparent transmission mode, supporting baud rates up to 115.2kbps. Ideal for wireless serial communication in SCADA systems.

Who needs this products, such as wireless remote I/O modules?

Engineers and system integrators working in building automation, environmental monitoring, and smart city infrastructure require these solutions to manage equipment in hard-to-reach areas. They are indispensable for professionals who need to implement reliable data acquisition in environments where traditional wired installations are impractical or too expensive.

Typical Applications:- Wireless sensor networks

- Remote equipment monitoring

- Building automation systems

- Environmental monitoring

Wi-Fi Enabled I/O Modules (Asia only)

Wi-Fi based remote I/O units provide high-speed wireless connectivity using standard network infrastructure, offering easy integration with existing IT systems. These solutions are particularly valuable for applications requiring real-time data transmission and remote access capabilities.

Typical Applications:

- Mobile equipment monitoring

- Temporary monitoring installations

- Smart city infrastructure

- Remote facility management

RF Wireless I/O Solutions (Available soon for sale)

RF wireless I/O modules operating at 433 MHz provide reliable communication in environments where other wireless technologies might face interference. These solutions offer long-range capabilities with minimal power consumption.

Featured RF Products:

- ICP DAS - RFU-IO-433 Industrial Wireless Modems RFU-IO-433 by ICP DAS 433 MHz RF wireless I/O module featuring configurable digital inputs and relay outputs, with transmission range up to 1km in open space.

How helps this products to optimize distributed process control?

These units allow for the efficient management of remote assets by integrating wireless technologies like ZigBee and Wi-Fi to maintain stable connectivity over long distances. By enabling local data collection and command execution, they help reduce network latency and ensure that automated systems remain responsive and coordinated across expansive operational sites.

Typical Applications:

- Agricultural monitoring systems

- Oil and gas field instrumentation

- Remote tank level monitoring

- Distributed environmental sensing

Choosing the Right Remote I/O Solution

When selecting remote I/O modules for your application, consider these key factors:

1. Match the module's protocol (ZigBee, Wi-Fi, RF) with your system requirements and existing infrastructure.

2. Ensure the device meets the temperature, humidity, and protection ratings for your installation environment.

3. Consider both the module's power needs and available power sources at remote locations.

4. Select modules with the appropriate mix and quantity of input/output channels.

5. Plan for future expansion by choosing systems that can easily accommodate additional modules.

Integration and Best Practices

Successful implementation of remote I/O systems requires careful planning:

- Conduct thorough site surveys for wireless installations

- Implement proper network security measures

- Establish regular maintenance schedules

- Monitor signal strength and quality

- Document all device locations and configurations

Conclusion

Remote I/O modules and units from ICP DAS provide flexible, reliable solutions for extending control system capabilities to distant locations. Whether through wired or wireless connections, these devices enable efficient data acquisition and control across diverse industrial applications. By selecting the appropriate technology (ZigBee, Wi-Fi, or RF) and properly implementing the system, engineers can achieve significant cost savings while improving system performance and reliability.

Find more Industrial Wireless Modems and Industrial Wireless Solutions in our catalog.