Today, reducing costs through improved energy efficiency is one of the priorities in the industry. To reduce the power consumption of devices, data on their current state, their power consumption and information about the quality of the supplied energy must be obtained. To help users obtain this kind of data, Moxa offers a wide range of products ranging from protocol gateways and remote I/O devices to Ethernet media converters.

Lets’ take a look on some of the already completed projects:

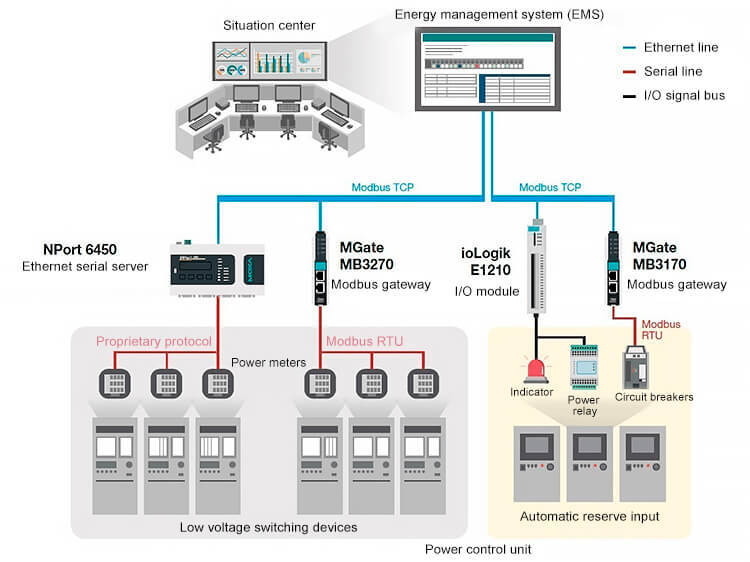

Project: Monitoring the quality of power quality management in data centers

One of the leading US companies operates and maintains multiple remote data centers. In order to ensure their uninterrupted operation, it is necessary to constantly monitor the power consumption and the state of the devices. The solution from Moxa allowed the company to create a power quality monitoring system, a system for collecting all the necessary data about devices and implement operational energy management.

The task

- Poll Modbus RTU devices via Modbus TCP protocol

- Get device status information

- Manage I/O channels

- Apply a single tool to configure hardware

The solution and the results

For project implementation, the company chose NPort 6450 secure terminal servers, MGate MB3170/MB3270 Modbus gateways and ioLogik E1210 remote I/O modules. This solution made it possible in a short time to create a system for monitoring energy consumption and ensure continuous interrogation of devices.

The advantages of Moxa products

- Wide range of products ranging from Modbus gateways and serial servers to remote I/O devices

- Convenient MXconfig and MCC tools for mass hardware configuration and maintenance

- Easy to use troubleshooting tools for Modbus problems

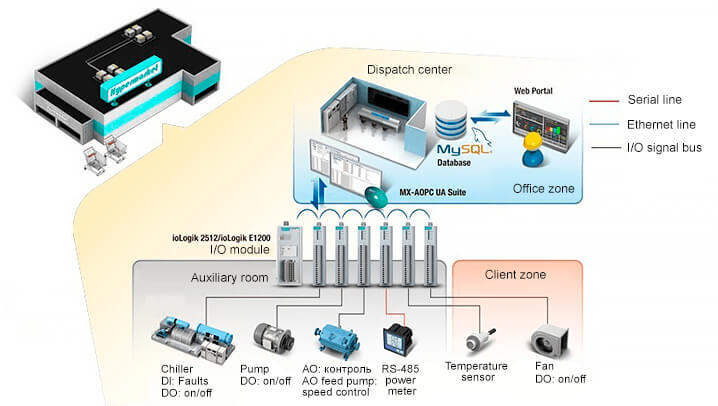

Project: Heating, ventilation and air conditioning system for a hypermarket

HVAC (Heating, Ventilation and Air Conditioning) is a technology that provides comfortable environment for people. Typically, HVAC systems in hypermarkets consume a huge amount of electricity, and in order to optimize their performance, it is necessary to constantly collect data on energy consumption and monitor equipment operation. It is necessary not only to integrate all chillers, pumps, fans and sensors into a single network, but also to create a single system for the automatic control of heating, ventilation and air conditioning.

The tasks

- Implement a system with automatic parameter changes depending on environmental conditions and hypermarket opening hours

- Provide monitoring of equipment energy consumption regardless of its location

The solution and the results

Moxa proposed to solve this task with modern IIoT technologies. The ioLogik E1200 series remote I/O system was chosen to automatically control chillers, pumps and fans based on the temperature in the hypermarket. IoLogik's built-in Click & Go Plus technology allows you to create hardware control logic without the need for programming. Also, the MX-AOPC UA OPC server made it possible to obtain all data about field devices in one place, significantly reduce traffic between devices and set up data sending to the MySQL database. In addition, a wide range of I/O modules made it possible to connect outdated equipment to a single system.

The advantages of Moxa products

- Easy-to-use Click & Go Plus technology allows you to create control logic without programming

- Wide range of I/O modules with DI, DO, AI, AO channels and RS-485, Ethernet interfaces

- Daisy-chain I/O modules reduce solution cost

- Easy device integration via OPC server MX-AOPC UA

You can find out more about the equipment mentioned in this article in the corresponding sections of our catalog:

For further technical information, inquiries about offers or placement of orders, please contact our sales team at sales@ipc2u.com