Introduction

The Industrial Internet of Things (IIoT) has led to unprecedented amounts of data being collected from machines, sensors, and devices across industries. However, transmitting all of this data to a central location for processing is neither practical nor efficient, especially in remote or distributed industrial systems. The solution? Bringing artificial intelligence (AI) to the edge. This enables real-time data processing and decision-making at the source, minimizing the need to send large volumes of raw data to cloud servers.

By deploying AI models on edge computing devices, businesses can perform critical tasks locally, reducing latency, saving bandwidth costs, and ensuring faster response times. This approach is known as the Artificial Intelligence of Things (AIoT). In this paper, we explore how to choose the right edge computing platform for AIoT applications and look at real-world examples to demonstrate the benefits of this technology.

1. Bringing AI to the IIoT

The advent of IIoT has revolutionized industrial data collection, giving businesses access to operational and environmental insights previously unavailable. Yet, despite the sheer volume of data collected, most of it remains unprocessed. This is because traditional data processing methods are slow and costly. As a result, industries are turning to AI and machine learning (ML) to automate data analysis and decision-making.

AI can process vast datasets, identify patterns, and generate actionable insights far faster than humans. For example, in manufacturing, AI can detect small product defects that would be nearly impossible to catch with manual inspection. Similarly, in transportation, AI can monitor vehicle performance in real-time and predict maintenance needs, helping to avoid costly breakdowns.

2. The Challenges of Managing IIoT Data

The number of connected IIoT devices is projected to reach over 40 billion by 2025. These devices generate an enormous volume of data, making it impossible for human teams to analyze all of it. In fact, most organizations only analyze a fraction of the structured data they collect, and even less of the unstructured data, such as video footage.

The number of connected IIoT devices is projected to reach over 40 billion by 2025. These devices generate an enormous volume of data, making it impossible for human teams to analyze all of it. In fact, most organizations only analyze a fraction of the structured data they collect, and even less of the unstructured data, such as video footage.

3. Combining AI and IIoT for Smarter Operations

Integrating AI with IIoT opens the door to enhanced efficiency and reduced human error. The AIoT (Artificial Intelligence of Things) leverages AI technologies to analyze IIoT data, enabling systems to optimize operations, predict failures, and reduce manual labor. In various industrial sectors, AIoT helps improve data analysis, enhance human-machine interactions, and streamline decision-making.

AI technology includes machine learning (ML), a subset of AI that enables systems to learn from data and improve over time. Within ML, deep learning (DL) focuses on training neural networks with vast datasets to recognize patterns and make decisions autonomously. These capabilities are especially useful in industrial applications like automated inspection, predictive maintenance, and smart transportation systems.

4. The Shift to Edge Computing

IIoT systems generate such vast quantities of data that sending everything to a cloud or central server for analysis is impractical. In many industries, particularly those with distributed or remote systems, reliable connectivity and sufficient bandwidth are not always available. Even when possible, transferring massive amounts of data can result in high costs and delays in critical decision-making.

Edge computing solves this problem by processing data closer to the source, minimizing transmission costs and improving response times. By running AI models directly on edge devices, businesses can perform real-time analysis, enabling faster and more efficient operations.

5. Choosing the Right Edge Computer for AIoT

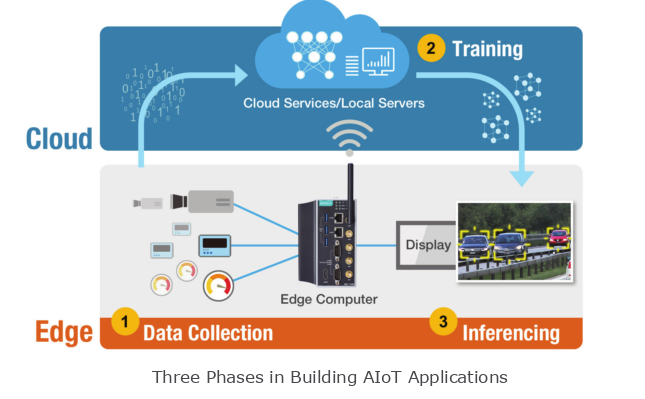

When implementing AI in industrial IoT applications, selecting the right edge computing platform is crucial. Although the training of AI models still happens in the cloud, the inferencing—the process of making predictions based on new data—happens on the edge. This requires a hardware platform that can support the necessary AI algorithms and processing power. Here are the key factors to consider:

- Processing Requirements: Different phases of AI implementation (data collection, model training, and inferencing) require different processing capabilities.

- Edge Computing Levels: Depending on your application's needs, choose between low, medium, or high edge computing power. Low-level edge computing can handle simple tasks like collecting data and sending it to the cloud, while high-level edge computing processes large volumes of data for real-time decision-making.

- Development Tools: The tools and frameworks you use (such as PyTorch, TensorFlow, or Intel OpenVINO) should align with your edge computer's capabilities.

- Environmental Conditions: Industrial applications often operate in harsh environments. Therefore, you need to consider factors like temperature tolerance, fanless design, and vibration resistance when selecting an edge computer.

6. Processing Requirements for AI Implementation Phases

AIoT computing power needs vary across the three phases of AI application development: data collection, training, and inferencing.

- Data Collection: In this phase, large amounts of data are gathered and preprocessed to remove errors and duplicates. The focus is on I/O and CPU capabilities, with processors like Arm® Cortex® or Intel® Atom®/Core™ typically used.

- Training: Training AI models requires powerful GPUs to handle complex algorithms and large datasets. This phase is usually conducted on cloud platforms like AWS, Google Cloud, or Azure, using frameworks such as PyTorch, TensorFlow, or Caffe.

- Inferencing: Once trained, the AI model is deployed on edge devices to make real-time predictions. This requires less processing power than training, with CPUs or lightweight accelerators like Intel® OpenVINO™ or NVIDIA® CUDA® being sufficient.

7. Real-World Examples of AIoT in Action

Case Study 1: AIoT for Railway Maintenance

A metropolitan railway system in East Asia sought to streamline its track inspection process. Instead of relying on human inspectors to visually check fasteners on railway tracks, they deployed an AIoT solution. High-resolution cameras mounted on trains captured images of the tracks during normal operations, and edge computers processed these images in real-time to detect any defects.

By using Moxa’s V2406C-KL1-T by MOXA | IPC2U rail computer, equipped with Intel® Core™ i7 processors and AI toolkits, the system automatically detected track fastener issues without stopping operations, significantly improving maintenance efficiency.

Related products can be found at Industrial Computers for Reliable Operations

Case Study 2: AIoT in Autonomous Mining Vehicles

In open-pit mining, autonomous haul trucks are increasingly being used to transport materials. AI-powered edge computers enable these trucks to operate without human drivers, navigating rough terrain and avoiding obstacles. Moxa’s MC-1220 — edge computer for AIoT , with Intel® Core™ i7 processors, provide the computational power needed to process real-time video and sensor data for self-driving operations, all while withstanding the harsh conditions of mining environments.

Related products can be found at Industrial Computers for Reliable Operations

8. Conclusion

AIoT is transforming industries by enabling faster, smarter decision-making at the edge. By moving AI inferencing to edge devices, businesses can reduce latency, lower data transmission costs, and increase operational efficiency. However, selecting the right edge computing platform is essential for successful implementation. By carefully considering your application’s processing, environmental, and development needs, you can deploy an AIoT solution that brings lasting business value.