In modern industrial automation systems (IIoT, Industry 4.0), efficient sensor data acquisition and actuator control are critical. Fieldbus I/O modules are indispensable components for this task. They act as "translators" and "hubs," connecting diverse analog and digital signals to Fieldbus systems and industrial network protocols. This enables centralized management of distributed devices, significantly simplifying installation and diagnostics while enhancing system reliability. Let's explore key protocols and solutions from ICP DAS, available on our website.

What Are the Key Advantages of Fieldbus I/O Modules?

These components provide efficient sensor data acquisition and deterministic data transmission for real-time control in automated environments. They significantly simplify system installation and diagnostics by enabling centralized management of distributed devices across various industrial protocols.

What are Fieldbus I/O modules and how do they function?

This product type serves as specialized translators and hubs that bridge diverse analog or digital signals with industrial network standards. They facilitate seamless communication between field equipment and central control units, ensuring that different hardware components can work together within a unified system.

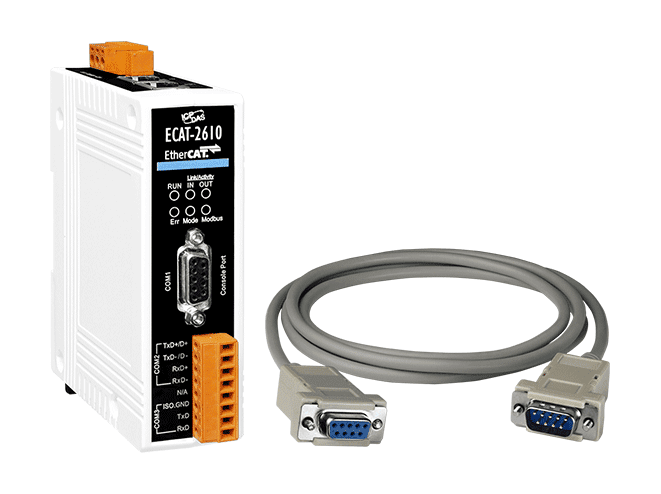

EtherCAT

EtherCAT (Ethernet for Control Automation Technology) is one of the fastest industrial protocols, operating over Ethernet. It provides deterministic data transmission with minimal latency, making it ideal for real-time control, robotics, and high-speed machinery.

- ICP DAS - ECAT-2610 : 16-channel analog input module (0~20 mA, 0~5 V, ±10 V), 16-bit resolution, galvanic isolation.

- ICP DAS - ECAT-2611: 8-channel analog output module (0~20 mA, 0~5 V, 0~10 V), 16-bit resolution, overload protection.

Applications: Motion control, synchronized high-frequency data acquisition, complex conveyor systems.

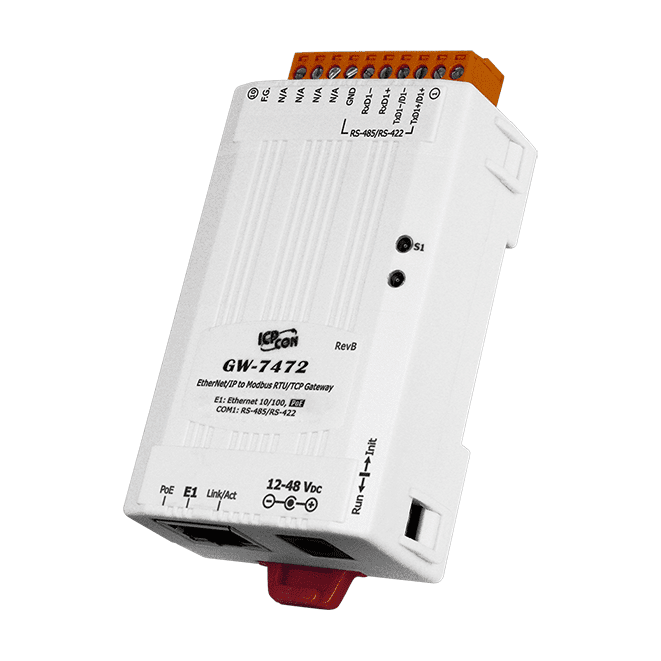

EtherNet/IP

EtherNet/IP (EtherNet Industrial Protocol) is an open standard using Ethernet and the CIP (Common Industrial Protocol) for real-time data and configuration. Widely adopted, especially in North America.

- ICP DAS - GW-7472: Compact gateway supporting EtherNet/IP Slave, integrating RS-485 devices.

- ICP DAS - GW-7473: EtherNet/IP Slave gateway integrating CANopen devices.

Applications: Integration with Allen-Bradley PLCs, SCADA systems, production line control, data collection.

BACnet

BACnet (Building Automation and Control Networks) is a specialized protocol for BMS/BAS, HVAC, lighting, and security systems. Ensures interoperability between equipment from different manufacturers.

- ICP DAS - GW-2492M: BACnet IP/MSTP Server & Client gateway supporting Modbus RTU/ASCII/TCP Slave.

- ICP DAS - GW-2139M: BACnet MS/TP (RS-485) gateway connecting Modbus RTU devices.

Applications: HVAC, smart buildings, energy monitoring.

PROFINET

PROFINET – an open industrial Ethernet standard by PI – delivers real-time transmission (RT, IRT) and IT integration. Dominant in European industry.

- ICP DAS - I-7580: PROFINET I/O device controller for distributed I/O stations.

- ICP DAS - GW-7663: PROFINET IO Device gateway integrating Modbus TCP/RTU/ASCII devices.

Applications: Production automation, Siemens PLC integration, process control.

CANopen

CANopen – based on CAN – is known for reliability, flexibility, and low cost. Popular in transport, medical, and specialized automation.

- ICP DAS - I-7232D: Universal I/O module with CANopen interface.

- ICP DAS - GW-7433D: CANopen Master gateway connecting up to 32 Modbus RTU devices.

Applications: Mobile machinery, medical equipment, machine tools, access control.

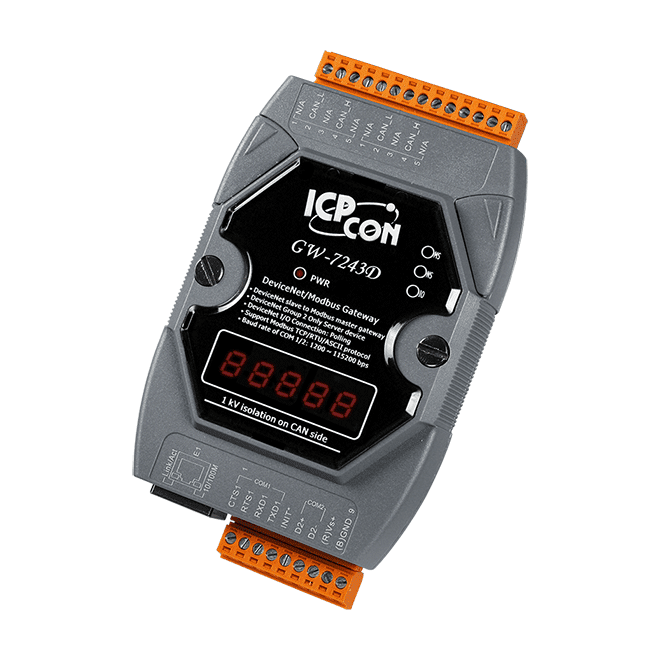

DeviceNet

DeviceNet is a fieldbus-level protocol (based on CAN) for connecting sensors, actuators, and simple I/O devices. Known for simplicity.

- ICP DAS - GW-7243D: DeviceNet Master gateway connecting Modbus RTU devices.

- ICP DAS - GW-7434D: DeviceNet Slave gateway integrating Modbus TCP/RTU/ASCII devices.

Applications: Pushbuttons, sensors, indicators, drives – especially with Allen-Bradley PLCs.

PROFIBUS

PROFIBUS DP – a long-established and widely used protocol – provides high-speed communication between PLCs and remote I/O modules.

- ICP DAS - GW-7552-B: PROFIBUS DP Slave gateway integrating Modbus RTU/ASCII/TCP devices.

- ICP DAS - GW-7557-B: PROFIBUS DP Slave gateway connecting CANopen devices.

Applications: Legacy PROFIBUS upgrades, distributed I/O, process automation.

Who needs this products, such as industrial communication modules?

Professionals involved in industrial automation, building management, and transportation systems require these solutions to connect field-level devices to high-level networks. They are essential for engineers who need to integrate legacy equipment with modern protocols without rebuilding their entire communication infrastructure.

How helps this products to streamline industrial data acquisition?

These modules facilitate the integration of disparate hardware by providing real-time protocol conversion and reliable signal isolation. By acting as a gateway between fieldbus systems and industrial Ethernet, they ensure stable and coordinated data exchange for complex robotic and manufacturing processes.