ICP DAS PAC I/O (Programmable Automation Controller Input/Output) modules are core components in modern industrial automation systems. They handle sensor data acquisition, actuator control, and communication between field-level devices and supervisory systems (SCADA/MES).

What are industrial I/O expansion modules and how do they function?

This product type consists of specialized plug-in units that expand the signal processing capabilities of a central controller through various analog and digital interfaces. They function by collecting data from field-level sensors and transmitting it to supervisory systems, providing essential protection against electrical interference in harsh environments.

Key features include:

- Robust Reliability: Operation in extreme conditions (-40°C to +85°C, vibration, EMI).

- Configuration Flexibility: Diverse interfaces (Ethernet, USB, RS-485) and signal types (DI/DO, AI/AO, RTD, Thermocouple).

- Modularity: Scalable architecture for system expansion.

- Industrial Protocol Support: Modbus TCP/RTU, CANopen, PROFINET (model-dependent).

What Are the Key Advantages of Programmable Automation Controllers?

These advanced control systems combine the high-performance processing of a PC with the rugged reliability of a traditional PLC to manage complex industrial tasks. They feature modular architectures and extreme temperature resistance, ensuring stable operation and easy scalability for mission-critical automation projects.

Primary applications: Process parameter monitoring (temperature/pressure/flow), production line control, building management systems (HVAC/power), and smart infrastructure.

Who needs this products, such as programmable automation controllers?

Engineers and system integrators working in sectors like energy management, factory automation, and smart infrastructure rely on these robust solutions for precise data acquisition. They are essential for professionals who need a modular hardware platform that can withstand extreme environmental stress while maintaining continuous communication with SCADA systems.

PAC I/O Series Overview

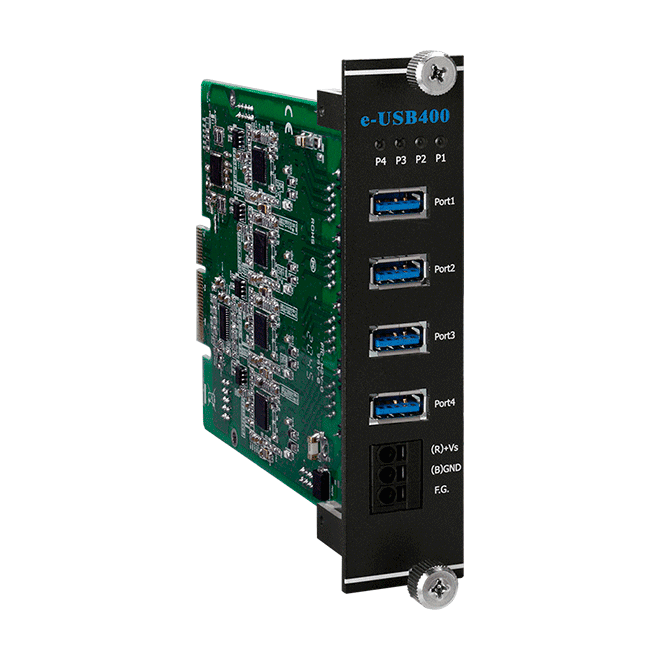

1. e-9K Series: Compact USB/Ethernet Modules (Available soon for sale)

Ideal for local data acquisition and PC integration. Features tool-free installation.

- e-9K Modules by ICP-DAS e-USB400 by ICP DAS: 4-channel USB analog input module (0-10V, ±10V, 0-20mA).

- e-9K Modules by ICP-DAS e-D96S by ICP DAS: 96-channel digital I/O module with 10/100 Ethernet and Modbus TCP.

Application: Lab test benches, mobile monitoring systems, PC-based DAQ.

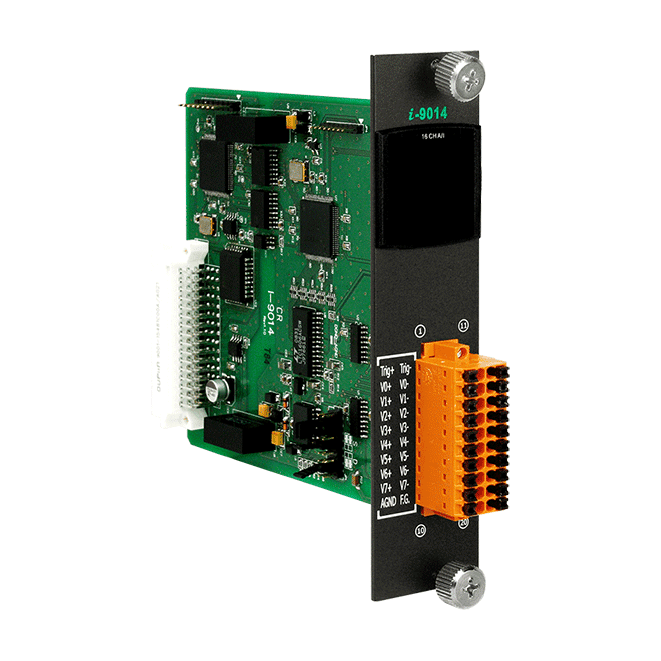

2. I-9K/I-97K Series: Industrial Ethernet Modules

Distributed Ethernet-based systems. Supports PoE and -40°C to +75°C operation.

- ICP-DAS I-9K Parallel Bus Modules I-9014 by ICP DAS: 4-channel analog input (TC/RTD/mV/V/mA) with Ethernet.

- ICP-DAS I-9K Parallel Bus Modules I-9053P by ICP DAS: 8 DI (dry contact) + 8 DO (transistor 0.5A) with PoE.

- ICP-DAS i-8K Parallel bus Extension Modules I-8014CW by ICP DAS: 4-channel isolated analog output (0-20mA/0-10V) with overload protection.

- ICP-DAS i-8K Parallel bus Extension Modules I-8041PW by ICP DAS: 16 DI (voltage/current sink) + 8 DO (relay 3A).

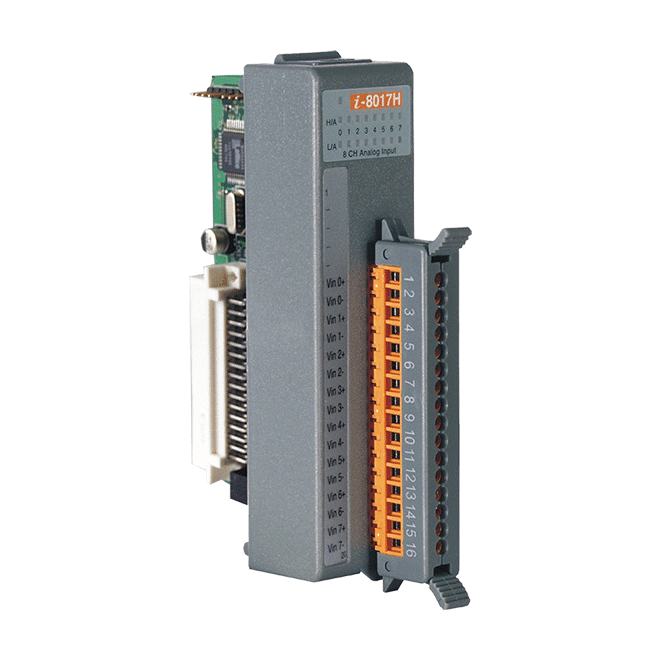

- ICP-DAS i-8K Parallel bus Extension Modules I-8017H-G by ICP DAS: 8-channel high-resolution analog input (±150mV to ±10V/±20mA).

- I/O Expansion Boards (XV/XW-Boards) by ICP-DAS XV107 by ICP DAS: 32 DI (dry contact/voltage) + 32 DO (transistor).

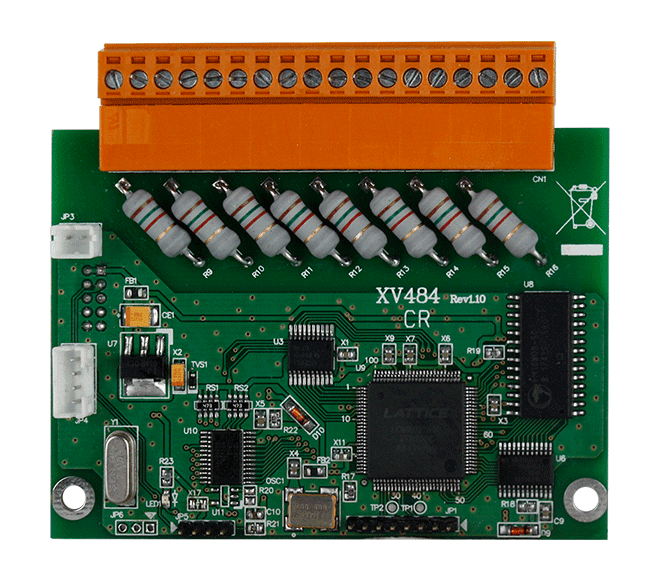

- I/O Expansion Boards (XV/XW-Boards) by ICP-DAS XV484 by ICP DAS: 8 AI (RTD) + 8 AO (0-20mA/0-10V).

Application: SCADA remote stations, facility monitoring, PLC peripheral expansion.

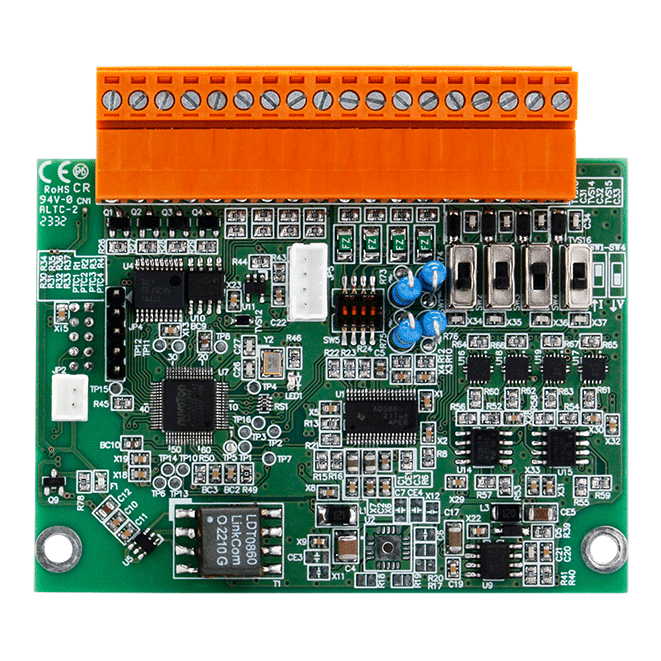

3. I-8K/I-87K Series (High Profile): DIN-Rail Modules

Standard DIN-rail mounting for control cabinets. Dual-watchdog design.

Application: Machine automation, pump/valve control, alarm systems.

4. I-8K/I-87K Series (Low Profile): Slim DIN-Rail Modules

Space-optimized for compact enclosures (22.5mm width).

Application: Retrofitting legacy systems, embedded control, tight-panel installations.

5. XV-board Series: High-Density Isolation Modules

Maximum channel density (up to 64 I/O) with 3 kV isolation.

Application: High-channel-count systems (power/water treatment).

6. XB-board Series: CANopen Distributed I/O (Available soon for sale)

Certified CANopen EN 50325-4 compliance.

- I/O Expansion Boards (XV/XW-Boards) by ICP-DAS XB310 by ICP DAS: 8 DI + 8 DO (transistor) with CANopen.

Application: Vehicle systems, CAN-based machinery, motion control.

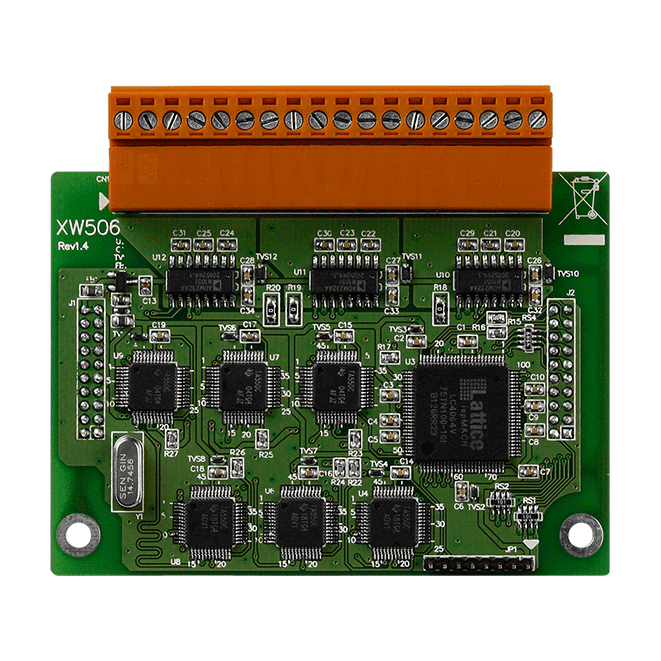

7. XW-board Series: Extended-Temperature Modules

Operates at -40°C to +85°C with conformal coating.

- I/O Expansion Boards (XV/XW-Boards) by ICP-DAS XW107 by ICP DAS: 32 DI + 32 DO (transistor).

- I/O Expansion Boards (XV/XW-Boards) by ICP-DAS XW506 by ICP DAS: 8 AI (TC/mV/V/mA) + 8 AO.

Application: Oil/gas, outdoor substations, metal processing.

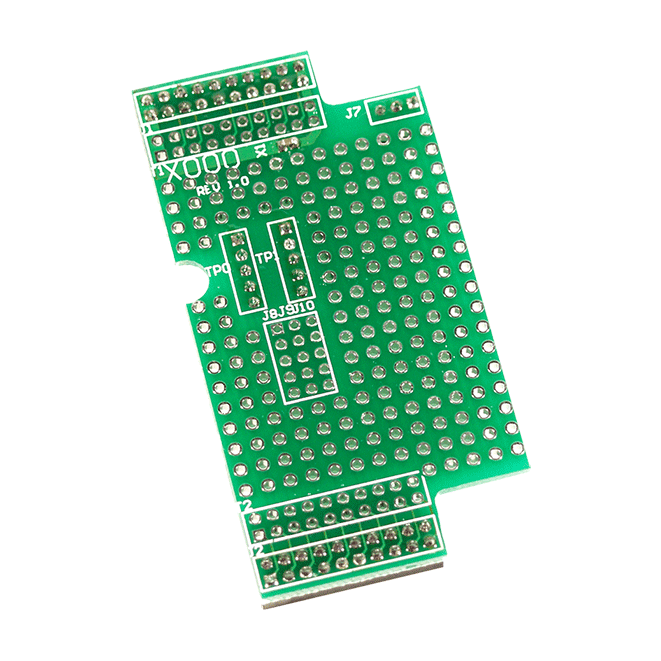

8. X-board Series: Cost-Effective I/O

Entry-level solutions with 3 kV isolation.

- I/O X Series Expansion Boards X000 by ICP DAS: 32 DI (dry contact).

- I/O X Series Expansion Boards X501 by ICP DAS: 8 AI + 8 AO.

Application: Budget automation, educational setups, simple monitoring.

9. GTP Expansion Boards (Phased out)

Backplane-compatible with GTP-series PLCs.

- Cellular GSM / GPRS Modems GTP-X301 by ICP DAS: RS-232/422/485 + CAN 2.0B + 8 DI.

Application: GTP PLC communication/DI expansion.

10. AI Accelerator Modules (Available soon for sale)

Edge AI processing with M.2 form factor.

- Cellular GSM / GPRS Modems Hailo-8L-M2 by ICP DAS: 13 TOPS neural accelerator.

Application: Embedded vision, predictive maintenance, edge inference.

How helps this products to streamline industrial control systems?

These units facilitate the integration of diverse field devices into a single network by supporting a wide range of industrial protocols and communication interfaces. Their compact, DIN-rail mountable designs help save cabinet space and reduce installation complexity, ultimately improving the overall efficiency and maintenance of automated production lines.

Conclusion

ICP DAS PAC I/O modules deliver scalable solutions for industrial automation—from basic data logging to AI-enhanced distributed control. Selection criteria: signal type/density, environmental rating, network protocols, and integration requirements.