Modbus Data Concentrators as a Powerful Tool for Integrating Industrial Systems

In modern industrial automation systems, a common challenge is integrating a multitude of disparate equipment—sensors, meters, variable frequency drives, and programmable logic controllers (PLCs)—into a unified network. Many of these devices use the proven Modbus protocol but often over different physical interfaces like RS-485, RS-232, or Ethernet. Manually collecting and converting this data is complex, resource-intensive, and prone to errors. This is where specialized devices, known as Modbus Data Concentrators, become essential.

Why are Modbus Data Concentrators Needed?

These devices act as information "translators" and "aggregators." Their primary task is to poll multiple slave devices on RS-485/232 networks, gather data from them, process it, and present it to the central management system (Master) in a convenient format via a high-speed channel, most commonly Ethernet. This relieves the main controller from the routine work of polling dozens of devices, significantly reduces network load, and simplifies project architecture. Concentrators ensure reliable communication, protocol conversion (e.g., Modbus RTU/ASCII to Modbus TCP), and often feature built-in software for easy configuration and diagnostics.

Key tasks addressed by data concentrators:

- Unifying devices with serial and Ethernet interfaces into a single network.

- The concentrator independently polls connected devices and provides pre-aggregated data.

- Seamless conversion between Modbus RTU, ASCII, TCP, and other protocols.

- Enabling data acquisition from remote, hard-to-access assets using wireless communication channels.

- Enhancing system fault tolerance through support for backup channels (e.g., Ethernet and 4G/3G).

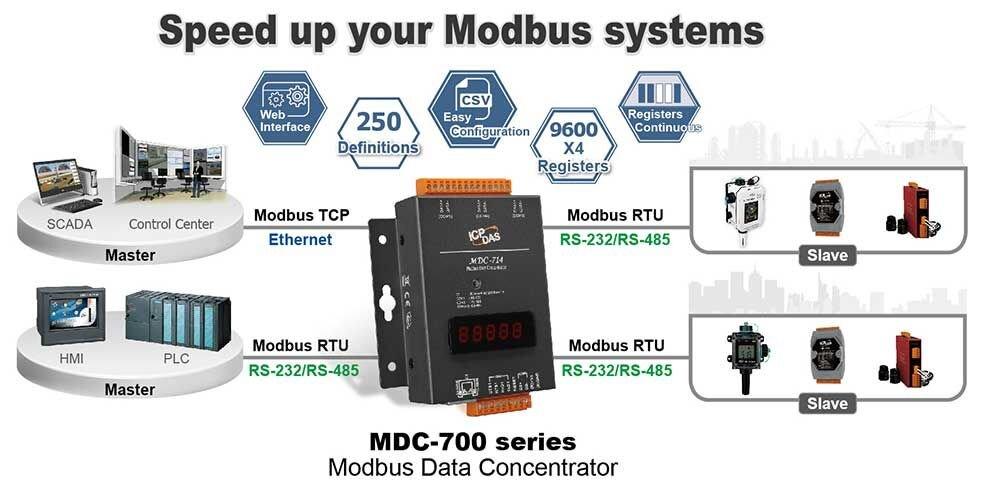

MDC-700 Series

This series represents a flagship solution for complex integration tasks. The devices feature a powerful processor, support for multiple protocols (Modbus Gateway, MQTT, JSON, OPC UA), and the ability to execute user-defined logic scripts in Lua. They are not merely converters but fully-fledged data pre-processors capable of filtering, processing, and reformatting information before sending it to a SCADA or MES system. They are ideally suited for building distributed data acquisition systems, IoT gateways, and comprehensive Industrial Internet of Things (IIoT) projects.

Application: Complex SCADA systems in manufacturing, smart city infrastructure, utility management systems (power, water, heating), and integration with cloud platforms.

ICP DAS - MDC-741 A Modbus data concentrator with dual LAN ports, two slots for communication modules (cellular, WiFi), and two COM ports.

ICP DAS - MDC-771 A high-performance concentrator with OPC UA Server support, two communication module slots, 4x LAN, and 3x COM ports.

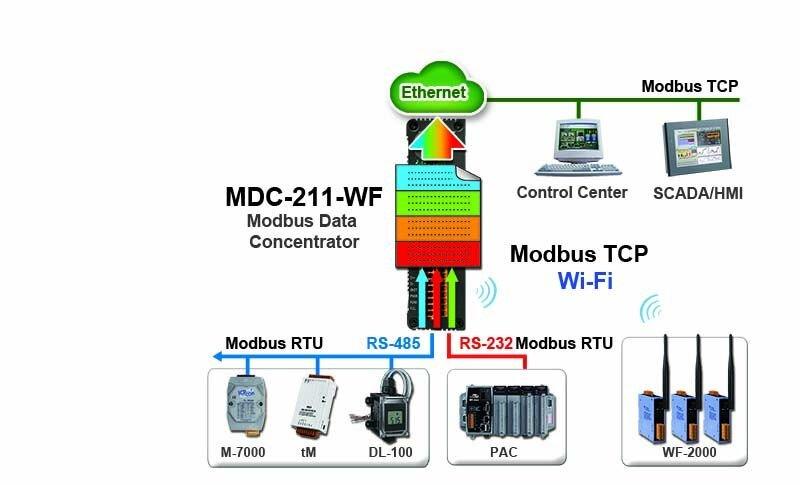

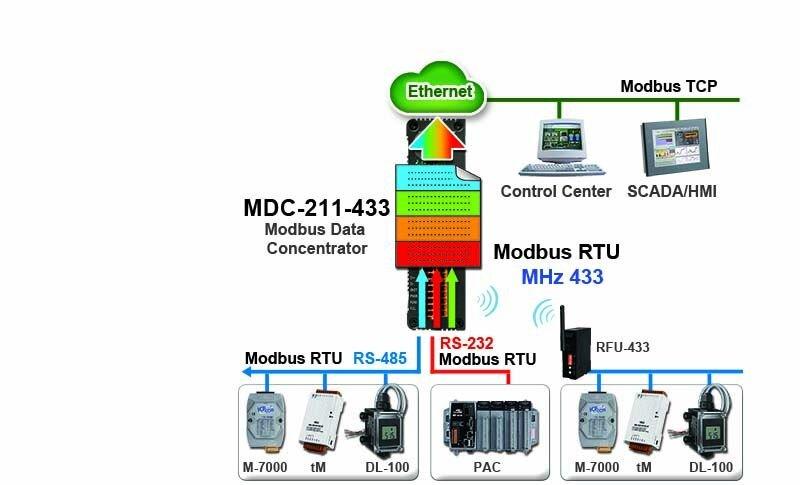

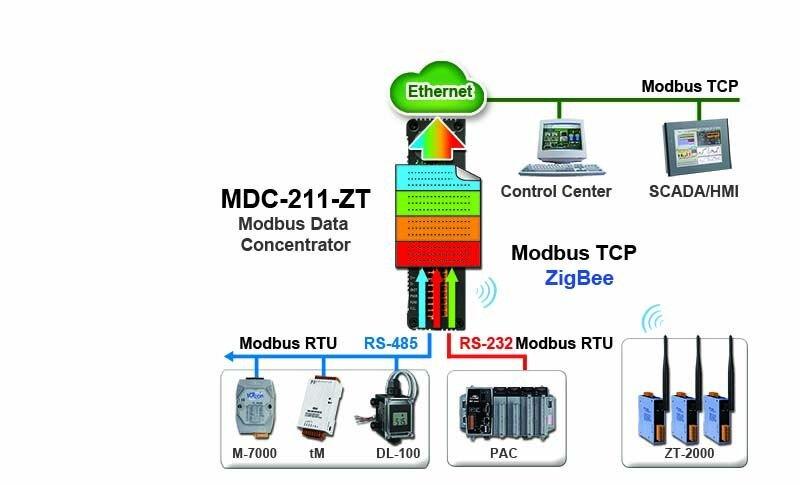

MDC-211 Series (Asia Only)

The MDC-211 series focuses on wireless data transmission, making it an ideal solution for remote monitoring of mobile or hard-to-reach assets. The models support various wireless technologies: LoRa (MDC-211-433), Wi-Fi (MDC-211-WF), and ZigBee (MDC-211-ZT). Their key advantages are small form factor, low power consumption, and the ability to operate in harsh environments, transmitting data from isolated areas to a central node via radio link.

Application: Energy resource metering (remote water/gas/electricity meters), environmental monitoring, streetlight control, and agricultural monitoring (greenhouses, fields).

ICP DAS - MDC-211-WF A wireless Modbus data concentrator with Wi-Fi and RS-485 interfaces.

ICP DAS - MDC-211-ZT A wireless Modbus data concentrator with ZigBee and RS-485 interface.

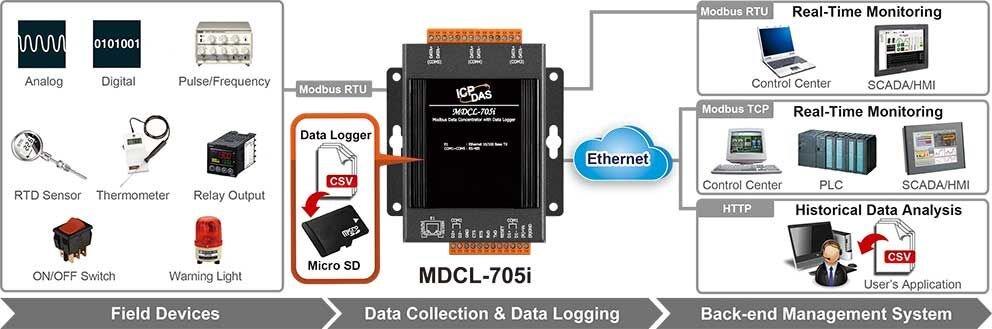

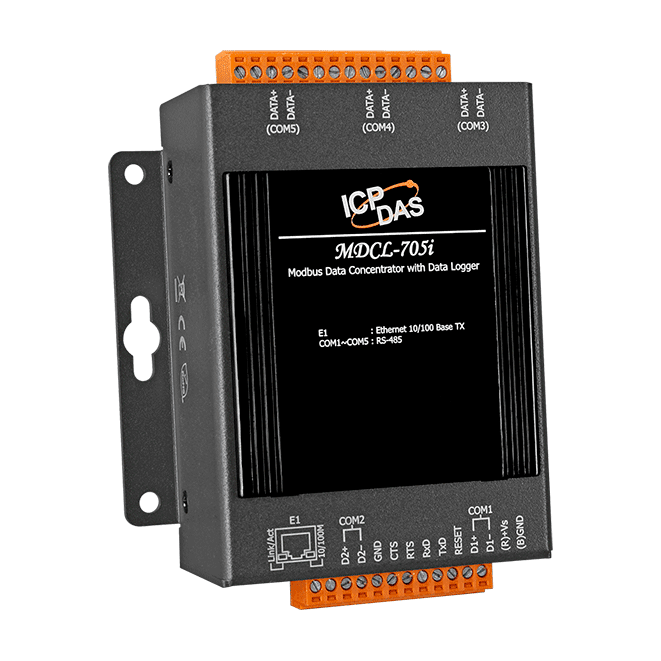

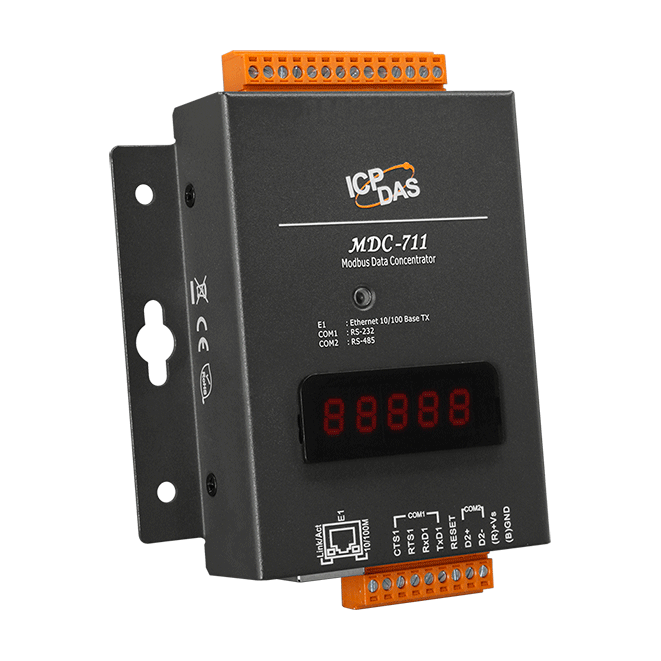

MDCL-705i / MDC-7xx Series

This line includes both compact devices (MDCL-705i) and more functional models (MDC-711). Their common trait is a focus on reliable operation in demanding industrial environments. They perform core functions of protocol conversion (Modbus RTU/ASCII to TCP) and data concentration, feature a wide operating temperature range, robust housings, and simplified configuration. These are reliable workhorses for standard integration tasks without the excess complexity of flagship models.

Application: Local equipment integration on a production line, connecting sensors and meters to a PLC or SCADA system, facilitating communication between controllers from different manufacturers.

ICP DAS - MDCL-705i A compact and cost-effective Modbus RTU/ASCII to Modbus TCP/Gateway protocol converter.

ICP DAS - MDC-711 An industrial Modbus data concentrator with 1x LAN and 2x COM ports, functioning as a gateway and data poller.

Selecting the appropriate ICP DAS data concentrator series depends directly on the specific technological task at hand. The powerful and versatile MDC-700 series devices form an ideal foundation for complex, distributed IIoT systems where deep data preprocessing is required, not just simple collection. The compact wireless gateways of the MDC-211 series provide a specialized solution for economical and efficient remote monitoring across vast areas. The reliable and easy-to-configure converters in the MDCL-705i and MDC-7xx series meet the needs of basic on-site equipment integration, ensuring stable communication in harsh industrial conditions.

In summary, ICP DAS's product portfolio covers the entire spectrum of modern automation needs—from simple interface conversion to building sophisticated IoT platforms. A well-chosen data concentrator not only solves compatibility issues but also significantly enhances the system's fault tolerance, scalability, and overall efficiency, reducing development and implementation costs.