The Role of 3.5” SBCs in Industrial Automation

The 3.5" form factor defines the physical dimensions of the board (146 × 102 mm), making it an industry standard. This standardization provides engineers with critical benefits: compact size, predictable mounting, and a rich ecosystem. These single board computers (SBCs) are primarily used in industrial, medical, and embedded applications. Unlike the consumer market (dominated by Raspberry Pi), industrial users value reliability, long-term availability, and extensive I/O options. Major global manufacturers include:

- Advantech (Taiwan) – Offers a wide range of Intel (Atom, Core i) and ARM-based models.

- AAEON (Taiwan) – Strong focus on Edge AI and industrial IoT.

- Axiomtek (Taiwan) – Known for boards tailored to extreme environmental conditions.

- ADLINK (Taiwan) – Specializes in testing, measurement, and edge computing solutions.

- ICOP (Taiwan) – Focuses on an often-overlooked niche: ultra-economical, low-power, legacy-compatible x86 platforms

Most major players concentrate on high-performance Intel Core or cutting-edge ARM-based SBCs — a premium market segment. In contrast, the segment of ultra-low-power, backward-compatible x86 boards — crucial for modernizing existing systems and building simple controllers — remains underserved.

Yet this segment is vital for industrial automation, where the priority is not peak performance but unwavering reliability, predictability, and guaranteed long-term availability. This is the niche that ICOP Technology occupies. Their focus lies in creating robust SBCs for harsh environments with full support for legacy interfaces and operating systems (including DOS, QNX, and RTOS). These make ICOP an ideal choice for control and data acquisition systems, particularly when migrating from aging industrial hardware to a modern yet compatible platform.

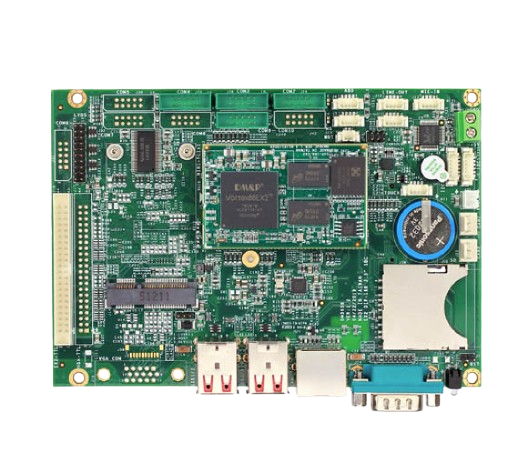

Key Technological Features of ICOP’s 3.5” SBCs

ICOP’s lineup for reliable, cost-effective legacy systems is based on several engineering principles:

-

Vortex86 Processor Architecture

ICOP’s hallmark is the Vortex86 SoC — an x86-compatible chip that integrates the CPU, graphics, and I/O on a single die, offering ultra-low power consumption. These systems enable fanless designs with minimal thermal management. For engineers, this means seamless code migration and wide OS support. Vortex86 boards run reliably on legacy systems like MS-DOS, QNX, Windows XP Embedded, and various Linux distributions. This makes them ideal for modernizing legacy equipment where rewriting software would be cost-prohibitive. A prime example is the VSX-6154-V2 — a board tailored for deeply embedded systems using the Vortex86SX chip. - Industrial-Grade Build and Reliability

Most ICOP boards are fanless and support extended temperature ranges (e.g., -20°C to +70°C), as with the VEX2-6415 , making them suitable for unheated workshops, outdoor enclosures, and transport systems. Some models go even further, supporting -40°C to +85°C. ICOP boards often feature wide voltage input ranges (e.g., 9–36V DC), simplifying integration into systems with unstable power sources. - Legacy Interface Support

A major advantage of ICOP is its commitment to legacy interfaces. These boards serve as a bridge between old and new technologies. On a single board, you’ll find ISA / PC/104 / PC/104+ buses, 4–10 COM ports (RS-232/422/485), LPT, PS/2, multiple LAN ports, CAN bus, USB, and GPIO. For instance, the VEX2-6427-10C4VNE offers an impressive 10 COM ports — a rare feature in modern hardware. ICOP guarantees long-term availability (7–10+ years), giving legacy automation systems many more years of life.

ICOP Product Lineup and Selection Guidance

ICOP offers several 3.5" board series, each tailored to a specific use case. Here's a closer look:

1. Vortex86-Based Series – For Maximum Reliability and Legacy Compatibility

This is ICOP’s flagship line, featuring ultra-low-power x86 SoCs. These boards are true workhorses for control and data acquisition applications and legacy system modernization. Passive cooling, predictable behavior, and support for even MS-DOS are standard. A typical model is the VEX2-6415 , often used as the central controller of a CNC machine or automation system. With up to 6 COM ports and a Vortex86EX2 processor, it’s ideal for polling sensors and actuators via RS-232/485. Fanless and rugged, it’s also available in extended temperature versions (-40°C to +85°C).

2. Intel-Based Series – For Projects with Higher Performance Requirements

For modern applications demanding higher computing power, graphics processing, or network throughput, ICOP offers Intel-based options. A great example is the IBW-35-E4 , powered by the Intel Atom x5-E8000. It features dual Gigabit LAN for high-speed networking and an HDMI output for modern HMI displays — ideal for operator panels or high-load IoT gateways.

3. Specialized and Budget-Friendly Solutions

This category includes compact, cost-efficient boards for projects that don’t need excessive features. A good example is the EBC-6413 , designed to be an affordable yet reliable gateway between operational (OT) and corporate (IT) networks. Based on the Vortex86DX3 processor, it has dual LAN ports and 4 COM ports — perfect for simple firewalls or industrial routers. Low power, low cost, no unnecessary extras.

Real-World Use Cases

- Industrial IoT Gateway

Collects data from dozens of RS-485 sensors and sends it to the cloud. Perfect match: EBC-358-6413E — LAN 1 connects to the factory floor, LAN 2 to the corporate network. - Telematics for Heavy Equipment

Monitors engine parameters over CAN bus, transmits via 4G (via Mini PCIe module). Built for this: VEX2-6427-10C4VNE . - CNC Controller Core

Real-time drive control under RTOS or DOS. The proven, reliable VEX2-6415 excels in this role.

Conclusion

In conclusion, ICOP’s 3.5” SBCs fill a well-defined and essential niche in the automation ecosystem. Their key strengths lie in exceptional reliability, x86-compatibility for effortless migration, a wealth of industrial interfaces, and guaranteed long-term availability.

By choosing ICOP, engineers invest not in raw gigahertz or benchmark scores, but in what truly matters for industrial automation — stability, predictability, and low total cost of ownership over the years.