Modern industrial automation requires the integration of vast amounts of data from various sources, fast response times to changes, and high equipment reliability. nDAS (Network Data Acquisition System) solutions make it possible to achieve these goals by connecting all processes, devices, and data into a single ecosystem. Let’s take a closer look at how nDAS improves performance and reliability in industrial automation.

What Is nDAS, and What Role Does It Play in Industrial Automation?

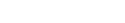

nDAS is a comprehensive system for real-time data collection, processing, and transmission. Its primary goal is to enhance the manageability and efficiency of industrial processes. nDAS is a flexible and powerful platform that integrates easily with various protocols and standards (such as Modbus RTU/TCP, OPC UA, SECS/GEM, and REST API), making it compatible with the existing infrastructure of most enterprises. The implementation of nDAS does not require a complete replacement of equipment, which reduces costs and eases the transition to digital technology. The system can connect to numerous data sources (sensors, controllers, cameras), gathering information and transmitting it for further analysis and visualization.

1. Enhancing Performance Through Rapid Data Processing

One of nDAS’s key functions is to optimize equipment performance and minimize downtime. With support for Modbus RTU/TCP and OPC UA protocols, nDAS allows real-time monitoring of equipment conditions such as temperature, vibration, and load. For example, the nDAS-6000 by NEXCOM | IPC2U model from NexAIoT offers a 24-bit analog input function, enabling operators to gather more detailed insights into processes.

nDAS’s high performance is also driven by its local data processing capabilities (edge computing), which reduces latency associated with sending data to a server or cloud. nDAS performs preliminary data analysis on-site, identifying critical parameters and transmitting them to the cloud or central control system for further processing. As a result, companies can make faster decisions and minimize equipment downtime.

2. Reliability and Data Security

nDAS’s stability and reliability are achieved through built-in data redundancy and disaster recovery support. The nDAS-6000 by NEXCOM | IPC2U model includes dual LAN ports, enabling backup network configurations that reduce the risk of lost connections with devices. In case of a failure, the system automatically switches to the backup channel, preventing downtime. Moreover, nDAS supports data backups, ensuring data preservation during malfunctions. For many industries, where data loss is unacceptable, this is a crucial advantage. On the cybersecurity level, nDAS includes protocols such as SECS/GEM, which ensure protection against unauthorized access and compliance with industry security standards. nDAS also supports notifications and reports via multiple channels (LINE, WeChat, email, Teams), allowing personnel to be promptly informed of potential issues.

3. System Flexibility and Scalability

One of nDAS’s significant features is its flexibility. The system supports multiple connection options, including LAN, RS-485, RS-232, Wi-Fi, and other interfaces. This facilitates easy integration of nDAS into existing infrastructure and adaptation to the specific needs of the enterprise. nDAS’s scalability allows easy addition of new devices and system expansion as the company grows. The nDAS-6000 by NEXCOM | IPC2U model supports multiple interfaces and I/O modules, making it a versatile platform for companies requiring flexibility and scalability.

4. Smart Analytics and Predictive Maintenance

Also provides intelligent analytics and predictive maintenance, helping enterprises identify potential problems before they occur. With support for Python functions and logic blocks, nDAS can process complex algorithms and perform data analysis for predicting equipment failures. This not only reduces maintenance costs but also improves overall production efficiency. By leveraging technologies such as machine learning and artificial intelligence, nDAS can detect hidden patterns in data and suggest optimizations that might otherwise go unnoticed. For instance, the system can identify anomalies in equipment operation based on historical data and alert personnel of potential failures before they happen.

5. User-Friendly Interface for Customization

One of nDAS's standout features is its VIC-Flow software, which provides a drag-and-drop interface. This tool empowers users to design customized functions without needing extensive coding knowledge. For more advanced customization, Python can be utilized within the interface, allowing for the creation of user-defined function blocks. This level of adaptability not only makes the system more efficient but also gives users greater control over their automation processes.

6. Cost-Effective Solution with High Accessibility

A key advantage of nDAS is its affordability, making it accessible for a wide range of customers. Unlike many high-end industrial solutions that come with a hefty price tag, nDAS delivers advanced functionality without compromising on quality, providing excellent value for money. The drag-and-drop software interface, cloud storage compatibility, and robust protocol support make it a user-friendly option, reducing training time and costs. This affordability, paired with a user-centric design, is a significant selling point that sets nDAS apart in the competitive industrial automation market.

7. nDAS Applications Across Various Industries

nDAS has applications across various industries, such as:

- Automotive Industry: Monitoring and controlling equipment conditions on assembly lines.

- Energy Sector: Data collection from sensors to monitor power plant conditions and prevent accidents.

- Semiconductor Industry: SECS/GEM support for equipment operation and data analysis in production processes.

- Agriculture: Collecting data on temperature, humidity, and other parameters to manage growing conditions.

Each of these industries benefits significantly from implementing nDAS, improving productivity, enhancing quality control, and reducing costs.

Conclusion

nDAS is a powerful and flexible platform that takes industrial automation to a new level. The system offers high performance by integrating with various protocols and providing real-time data processing. nDAS minimizes equipment downtime and increases operational reliability, making it indispensable for companies seeking to optimize their processes. With nDAS, enterprises can not only enhance the performance and reliability of their systems but also prepare for future growth, thanks to its scalability and flexibility. In a world where industrial digitalization is accelerating, such solutions are essential for maintaining a competitive edge in the market. Related products can be found at Industrial Monitoring and Measuring Devices