In this article, we will take a quick look at the architecture and structure of flash memory and the process of choosing an industrial SSD.

An SSD (Solid State Drive) is a non-mechanical storage device consisting of flash memory chips and a microcontroller.

Flash memory is a kind of semiconductor technology called EEPROM (Electrically Erasable Programmable Read-Only Memory).

Content:

NOR and NAND architectures

There are two flash memory architectures - NOR and NAND, differing primarily in the method of connecting memory cells. Each of them has its own advantages and disadvantages, which determine the scope of application of each technology.

NOR memory was named so after the special data markup (logical Not OR). The NOR design uses a classic two-dimensional conductor matrix with one cell at the intersection of rows and columns.

With this arrangement, NOR provides high-speed, random access to information, and can write and read data at a specific location without having to access memory sequentially. Unlike NAND memory, NOR memory can access data up to one byte.

NOR technology is at advantage in situations where data is being written or read randomly. Therefore, NOR is more often used as program memory for microprocessors, for example, BIOS memory of a personal computer, memory for storing small auxiliary data, or for storing an operating system in cell phones and tablets.

NAND memory is named after another special data markup (logical Not AND). Basically, the matrix is the same as in NOR, but instead of one cell (transistor), a column of cells in series is found at each intersection.

NAND memory writes and reads data at high speed, in sequential read mode, arranging data into small page blocks. NAND memory can read and write information page by page, but unlike NOR, it cannot access a specific byte.

The price of an SSD using NAND architecture is less than NOR; also, NAND chips have a higher density of data. NAND architecture is commonly used in SSDs, USB drives, memory cards, mobile phones for storing user information, and other devices in which data is written sequentially.

In this article, we will mostly focus on the NAND architecture as it is used in most modern solid-state drives.

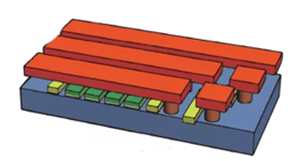

3D NAND, a second generation of NAND flash

The main reason for the development of a second generation of NAND flash was the manufacturers’ desire to reduce the cost of flash memory, considering that the technical process had already approached 10 nanometers and further crystal size reduction along the X and Y axes had became impossible.

An important feature of the new 3D NAND architecture is the vertical layout of the cell blocks on the chip, where one more axis has been added - the vertical Z axis. The cells are superimposed in layers, as a result, each crystal has a multilayer 3D structure.

This vertical structure provided a breakthrough in flash memory density. The emergence of the vertical axis removed the dependence on other axes, due to which the need to reduce the crystal disappeared, and many manufacturers returned to the 30-nanometer process technology, which ultimately led to a decrease in the cost of manufactured products.

Memory cells

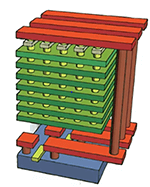

A memory cell can store 1, 2, 3 or 4 bits of information. Physically, all 4 types of NAND memory cells are composed of the same transistors, only the amount of charge stored by the cell differs.

In single-bit cells there are only two charge levels on the floating gate. Such cells are called single-level cells (SLC). SLC memory has the highest price, highest performance, lowest power consumption, highest write speed and Program/Erase cycles.

More charge levels are found in multi-bit cells; that’s why they are called multi-level cells (MLC). MLC devices are cheaper and have more capacity than SLC devices, but they also have a higher access time and their maximum number of rewrites is much lower. Usually, MLC means memory with 4 charge levels (2 bits) per cell.

Cheaper (in regards of capacity) memory with 8 levels (3 bits) is called TLC (Triple Level Cell). TLC also lags behind SLC and MLC in read/write speed and the number of Program/Erase cycles.

There are also devices with 16 levels per cell (4 bits), QLC (quad-level cell). QLC technology is the most affordable in terms of the cost of storing 1GB of data, nearly approaching the cost of traditional hard drives.

Tiered memory dominates the market today. Nevertheless, SLC-products, despite the many times lower capacity and high cost, continue to be developed and manufactured for critical applications.

Choosing a flash drive with Innodisk solutions as an example

The choice of solid-state drive for your computer depends on several factors, the most important of which are: form factor, scope of application, operating conditions, speed and resources.

Form factors

The process of selection of any storage device begins with the slot and connector to install it. There are many form factors and interfaces available on the market today for connecting flash drives. It’s safe to say that the most common is the 2.5-inch form factor with a third-generation SATA connection interface. A 2.5" SATA connector can be found in almost every modern personal computer or laptop and is universal for installing a classic hard drive, as well as a solid-state drive based on flash memory.

Available form factors:

Operating conditions

An industrial computer differs from its customer-class counterpart in many ways, but the most prominent differences are the capability to operate in 24/7/365 mode without interruptions or downtime, resistance to temperature spikes, vibrations, shock and high humidity. These demanding requirements to an industrial computer apply to all of its components, including storage devices.

Depending on the degree of protection against these factors, the price of a flash memory device also differs. Therefore, it is important to determine in what operating conditions the final product will be used and what temperatures and spikes it will be exposed to.

Flash memory drives can be divided into two major classes:

Resource and speed

As we have already said, there are flash memory cells capable of storing 2 (SLC), 4 (MLC), 8 (TLC) or 16 (QLC) charge levels. In industrial Innodisk flash memory, only the first three technologies are used, due to stringent requirements for reliability. The algorithm for processing a charge consisting of 16 levels is too complex, and in conditions of voltage surges and possible radio frequency interference that may occur during the operation of an industrial computer, this can lead to a rapid decrease in the residual resource and, as a result, data loss.

In addition to the three main types of memory cells, there are enterprise MLC cells - eMLC. Innodisk calls these cells iSLC; they are the middle ground between the endurance of SLC and the more affordable price of MLC.

ISLC drives demonstrate performance and reliability comparable to SLC products, but are built on MLC memory hardware, making them a more affordable solution suitable for servers and enterprise segment systems.

When using SSD based on iSLC technology, you can be sure of data safety - the service life is increased several times compared to standard MLC products.

Here is a comparison table of memory cells used in flash drives, in terms of price/endurance/speed.

Let's compare four models of Innodisk solid-state drives of 2.5" SATA form factor with a capacity of 128 Gigabytes, extended temperature mode -40 degrees C to 85 degrees C, designed to be used in embedded systems.

| Model name, SSD 2.5” 128 GB, -40° to 85°C, Embedded series | NAND cell type | Cost, USD | Number of rewrite cycles (P/E) | Read/write speed (MB/s) |

|---|---|---|---|---|

| DES25-A28DK1EW3QF | 3D TLC | 100,40 | 3000 | 550/150 |

| DES25-A28M41BW1DC | MLC | 192,17 | 3000 | 530/190 |

| DHS25-A28M41BW1DC | iSLC | 429,18 | 20 000 | 540/400 |

| DES25-A28D06SWCQB | SLC | 1690,39 | 60 000 | 490/430 |

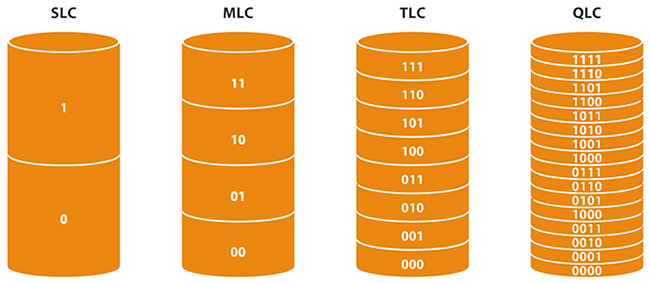

How to read Innodisk model names

Large industrial flash memory vendors such as Innodisk have a wide variety of devices with similar specifications across a range of product lines.

In order to find your way across this abundant selection and choose a drive most suitable for your specific tasks, you first need to figure out what kind of SSDs are available and what they are geared towards.

As an example, we will look at the model name of a 2.5-inch SATA SSD:

(2.5" SATA SSD) – form factor: points to the flash storage device design.

(3MV2-P) – series name. Let’s take a closer look each symbol in turn and what it represents:

(3) – generation: 1, 2, and 3.

First, second and third generation models are available.

(M) indicates the NAND type: S, M, I, or T.

| S: SLC | High write speed, low power consumption, and high endurance. SLC Flash SSDs are highly reliable and better suited for mission-critical applications. |

| M: MLC | The main advantage of MLC flash memory is its lower cost due to its higher data density. This advantage makes MLC-based solid-state drives an excellent replacement for traditional HDDs. |

| I: iSLC | iSLC is an exclusive Innodisk software technology that improves data transfer rates and data quality to match the write speeds of SLC Flash drives. By using special flash memory management algorithms, iSLC increases the endurance of the SSD up to 20000 cycles. |

| T: TLC | TLC-based 3D Flash is a new technology with an updated architecture. This solution provides a higher density of information recording at a lower cost. |

(V) – scope of application, with the following series available: E, G, R, V, S.

| E: Embedded | Drives optimized for industrial-grade embedded systems |

| G: EverGreen | Decent speed and long service life |

| V: InnoREC | SSD for video surveillance |

| R: InnoRobust | Specialized series for the most demanding applications |

| S: Server | Server boot devices |

| I: InnoAGE | SSD with Microsoft Azure Sphere |

(2) – production series.

This number can range from 1 to 10, or there may be no at all. It has no significance when choosing an SSD-drive.

(-P) indicates the presence of a DRAM-based cache.

The clipboard (cache) is used primarily for storing the address translation table, which increases the speed of accessing flash memory and writing files.

For every 1GB of SSD storage, there must be 1MB of cache. Thus, an SSD with a capacity of 120-128GB must have 128 MB cache, a 240-256GB SSD must have 256MB cache, a 500-512GB SSD must have 512MB cache and a 960-1024GB SSD must have 1024MB cache.

SSD without DRAM buffer will slow down during long write operations of small files.

Innodisk SSD series

| Embedded | The Embedded series is the best solution for industrial-grade embedded systems because of its high reliability and long service life |

| EverGreen | The EverGreen series is built with an integrated external DRAM cache, which greatly improves data exchange speed and extends the lifespan of an SSD |

| InnoREC | InnoREC SSD drives are especially designed for video surveillance and have intelligent firmware algorithms that guarantee continuous, stable data recording |

| InnoRobust | The InnoRobust series meets all modern requirements for devices for critical applications. The series is fully compliant with aerospace and defense standards, including MIL-STD-810F/G and MIL-I-46058C. InnoRobust series solid-state drives are fully protected from dust, shock, vibration and extreme temperatures |

| Server | SATADOM server boot devices are designed for easy server integration, resulting in a robust solution, and certified for Windows Server 2016 Hyper V and VMware |

| InnoAGE | SSD with Microsoft Azure Sphere, which is a secure, high-level application platform with built-in interoperability and security for devices connected to the Internet |

In addition to the series listed above, Innodisk offers a unique product – the fireproof 3.5” Fire Shield SSD.

The3.5” Fire Shield solid-state drives are capable of withstanding open fire at 800C for 30 minutes, protecting the memory elements from external influences.

Conclusion

In this article, we have:

- learned what an SSD is;

- defined the term of flash memory and explored what NOR and NAND architectures are;

- figured out why the NAND architecture is better suited for SSD drives;

- found differences between the types of NAND memory cells (SLC, MLC, TLC, QLC);

- compared several Innodisk models, finding out what types of cells have the greatest durability and reliability, and which ones are affordable;

- defined what form factor is and how they are used in modern industrial PCs;

- analyzed what series of products exist and for what tasks they are best suited, using Innodisk SSD series as an example.

We hope this material is useful in easing your way into the vast world of industrial flash memory drives.

For further technical information, inquiries about offers or placement of orders, please contact our sales team at sales@ipc2u.com