Constructing well-connected and reliable networks in factory plants faces several problems. First of all, some factory plants such as steel or automobile factory are exposed in the environment with dusts, high moisture, humidity and even higher temperature. Devices placed in factory plants are easily affected by various noises which can result in unstable quality, increased cost and working hours. Secondly, some legacy machines in factory plants have only serial protocol in Industrial Automation applications and do not support Ethernet-based connections. Moreover, these devices may have high possibilities to suffer from ESD, EFT and surge. To reduce downtime and enhance productivity, it is also important to take redundant mechanism into consideration.

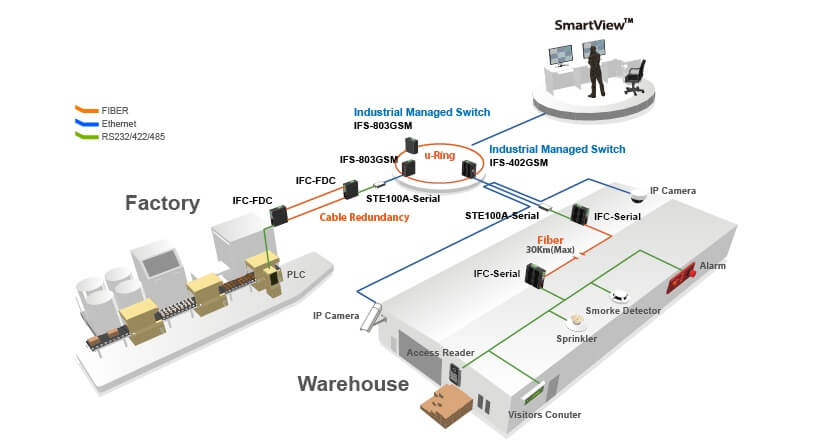

IFS-803GSM and IFS-402GSM switches support dual fiber, ring or u-ring redundancy. u-Ring can support up to 5 rings and can recover from a single point of failure in 10 ms. Besides that, they can be powered from two independent power sources for uninterrupted and stable operation. These switches have also the alarm relay contact and it can be wired into an alarm circuit which senses an alarm condition to operator when the contact is broken. Some models support PoE technology for connection, for instance, IP cameras.

IFS-Serial models support fiber and serial connectors such as RS-422/RS-485 and Serial ports are isolated (2.5KV) to minimize the risks of system instability or failures. IFC-FDC models can be connected in a cascade or "daisy chain" topology as well as creating ring architecture for fiber redundancy.

So, models which are depicted on the figure, has reliable industrial design (EMI and EMS certification) and trusted characteristics (wide operating temperature range (-40 to 75C) for significant industrial automation applications, especially in the critical environments.