Introduction

The conventional electronics manufacturing sector relies heavily on manual labor, featuring limited automation and narrow profit margins within the lower end of the supply chain. Escalating labor expenses and elevated standards for product quality have placed novel and substantial pressures on electronics firms. To counter this, integrating a comprehensive IT and control system with advanced automation can yield benefits for these companies. This encompasses cost savings through reduced labor expenditures and heightened production efficiency, along with the implementation of robust enterprise information management. Such measures ultimately bolster the competitive standing of these enterprises, enabling a shift towards elevated manufacturing practices.

System Requirements

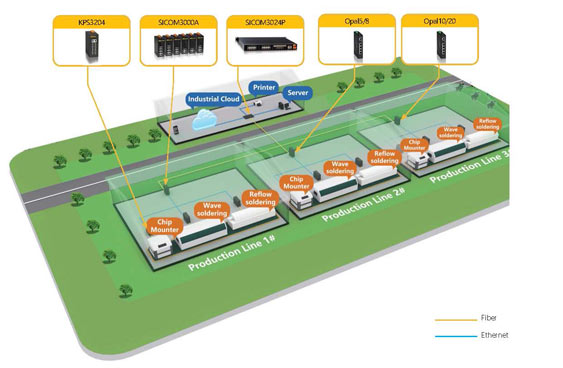

To provide access capability for Ethernet and serial devices in the system To provide fast failure recovery Easy network management and diagnostic functions To provide centralized management and remote management

Why Kyland

Industrial level Rackmount or DIN-Rail type Layer 2 management switch with fanless design, wide operating temperature, long MTBF Support Ethernet, serial, DI/DO access capabilities Support network redundancy with fast recovery <50ms, support RSTP

Recommended models

- Industrial IEC 61850-3 Ethernet Switches

- 19" Rackmount Managed Switches

- Managed DIN-Rail Mounted Switches

- SICOM6896G-H-12BS

- SICOM3024G-12G12GE-HV-HV

- SICOM3000A-8GE-L2-L2-PN